Workplace safety isn’t just about wearing the right helmet or checking the fire extinguishers.

It’s about creating an environment where risks are minimized before they even become visible.

And one of the most overlooked factors in that equation?

Lighting and electrical systems.

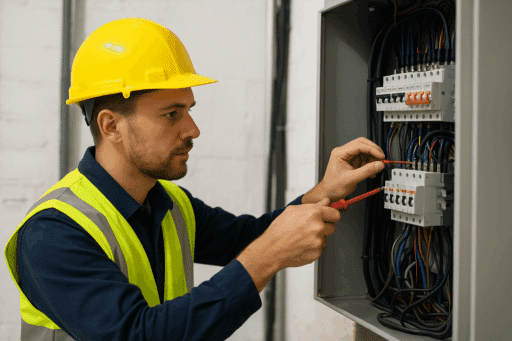

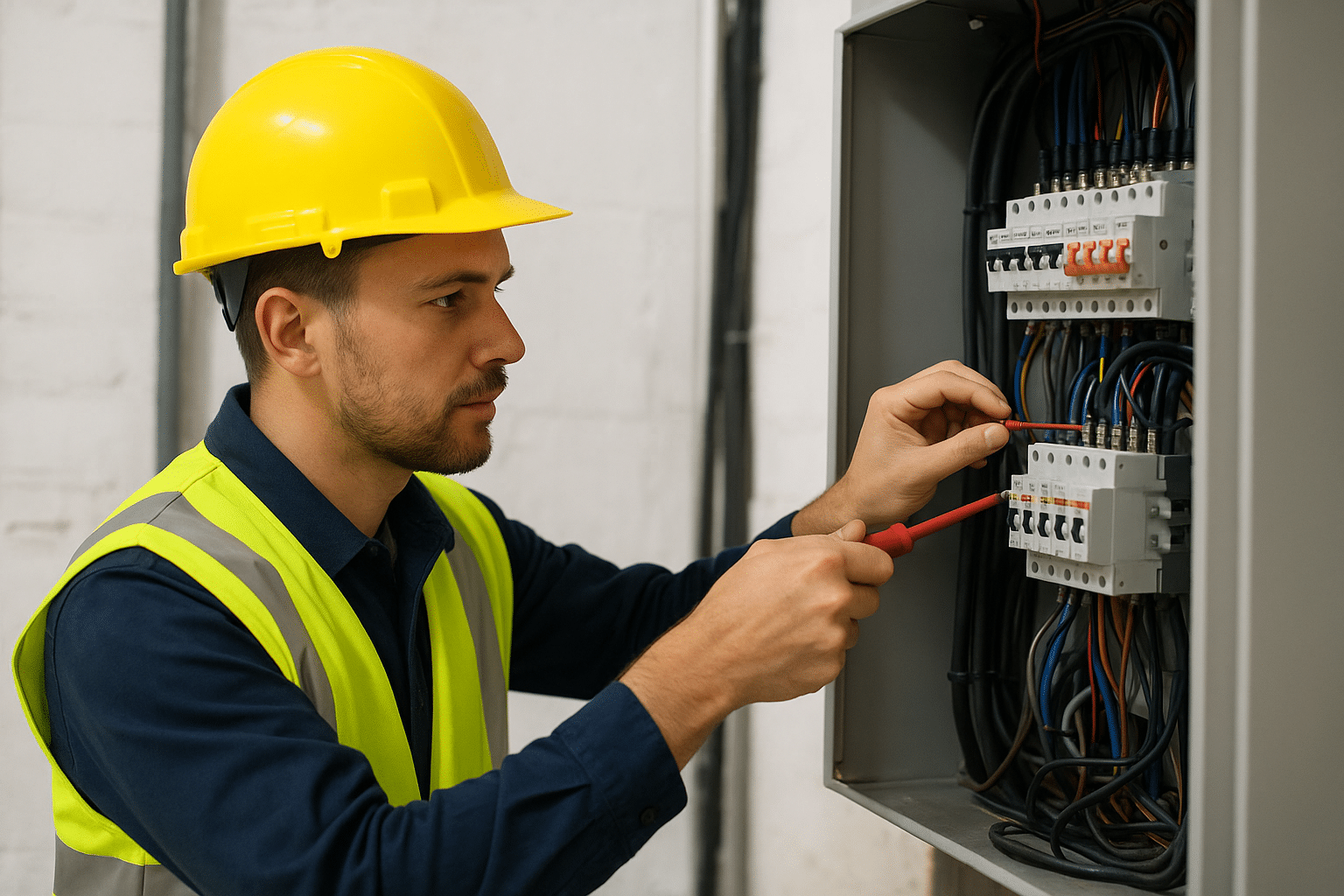

I’ve seen facilities spend millions on modern machinery while still working under outdated wiring or poorly planned lighting. That’s a recipe for trouble. In my years working with manufacturers, construction sites, and commercial facilities, I’ve learned that calling in top electrical contractors isn’t a luxury, it’s a necessity. They don’t just “install lights.” They prevent accidents, keep compliance officers happy, and help you sleep at night knowing the place won’t go dark during peak production.

Why This Topic Matters More Than You Think

Let’s start with the numbers.

According to the Electrical Safety Foundation International (ESFI), electrical hazards account for about 5.6% of all workplace fatalities. That’s not a small fraction when you consider how many incidents we’re talking about each year.

Between 2011 and 2023, there were 1,940 electrical-related fatalities in the U.S. Here’s the part that surprises most people, nearly three-quarters of those deaths happened to workers who weren’t electricians at all, painters, roofers, laborers. People just doing their jobs, but in environments where electrical risks were lurking in the background.

I remember visiting a small manufacturing plant in the Midwest a few years back. They were struggling with recurring breaker trips. At first, the manager shrugged it off as a minor nuisance. Then one day, a machine operator touched a panel that hadn’t been grounded properly. He was lucky, it was a mild shock. But it could’ve been worse. That was the turning point when they brought in certified specialists to overhaul the system.

The Link Between Electrical Safety and Lighting

Most people think of lighting as a comfort or a visual aid. I think of it as a safety barrier. Poorly lit areas hide hazards, loose cables, damaged outlets, water leaks near electrical points. Good lighting, on the other hand, helps workers spot risks before they become accidents.

It’s not just about brightness. Glare can be just as dangerous as dimness. Shadows can hide moving parts or trip hazards. Emergency lighting is another piece of the puzzle, if power fails, your workers shouldn’t be navigating in the dark to find the exits.

There’s also a productivity angle. Well-lit environments reduce eye strain, lower fatigue, and improve judgment. People simply make better decisions when they can see clearly.

Regulations and Standards You Can’t Ignore

Electrical safety in the workplace isn’t guesswork, it’s defined by standards.

Two of the most referenced are:

– NFPA 70E – This covers everything from lockout-tagout procedures to PPE requirements and safe work practices.

– NIOSH guidelines – They clearly state that unqualified personnel should keep at least 10 feet away from energized parts.

These aren’t suggestions. They’re legal and safety obligations. I’ve worked with companies that learned the hard way that OSHA citations can cost far more than prevention measures.

Practical Safety Strategies That Work

1. Identify Risks Before They Bite Back

This means inspecting overhead power lines, checking wiring conditions, and looking for overloaded circuits. According to ESFI data, contact with overhead power lines accounts for nearly 48% of electrical fatalities in the workplace.

I’ve walked into facilities where extension cords were practically woven into the workspace like vines. That’s not innovation, it’s an accident waiting to happen.

2. Design Lighting With Purpose

You don’t just put lights where there’s space. You plan them to minimize glare, eliminate dark corners, and keep high-risk areas visible.

Daylight integration, motion-activated lights for seldom-used areas, and strategically placed task lighting are worth considering.

3. Train Everyone, Not Just Electricians

Remember the statistic about non-electrical workers being the majority of victims? That’s why safety training should include everyone from the janitorial staff to the warehouse crew.

I once trained a team of office employees on how to shut down electrical equipment in an emergency. A month later, one of them prevented a small wiring fault from turning into a fire simply because she knew where the main switch was.

4. Maintain and Test Regularly

Testing isn’t just for compliance, it’s for peace of mind.

Include insulation resistance tests, earth-continuity checks, and leakage current measurements.

Visual inspections catch things numbers don’t, like scorch marks or frayed cables.

5. Follow Lockout-Tagout Without Exceptions

LOTO violations are still among the top OSHA citations every year. Skipping it to “save time” is the fastest way to put people in danger.

The Role of Signage and Equipment Labels

Clear labels on machinery and panels aren’t decoration. They’re silent warnings. Use modern ANSI Z535-compliant signs rather than outdated versions. Make them visible, weather-resistant, and multilingual if needed.

I once worked with a factory in Texas where half the crew spoke Spanish. They had plenty of warning signs, in English only. That gap got fixed after a near miss.

Lighting’s Double Duty in Safety

Lighting does more than prevent tripping or misreading gauges. It’s essential during maintenance. If a technician is inspecting cables in a poorly lit utility room, the odds of missing a small crack or worn spot rise dramatically.

I’ve seen maintenance teams bring their own portable lights simply because the installed ones weren’t cutting it. That shouldn’t be necessary if lighting design is done right from the start.

Implementation That Actually Sticks

Changing safety culture isn’t about putting up posters. It’s about a step-by-step plan:

1. Conduct a full risk assessment.

2. Audit electrical and lighting systems.

3. Schedule training for all staff.

4. Set a maintenance calendar and stick to it.

5. Upgrade signage and labels.

6. Improve lighting according to usage patterns.

7. Review performance metrics quarterly.

Real-World Case to Think About

In Maharashtra, India, over a five-year period, more than 6,700 people died from electrocution, with thousands more injured. That’s not a developing-world problem, it’s a human problem. Faulty wiring, poor safety culture, and lack of awareness are universal risks.

Measuring Success

You can’t manage what you don’t measure.

Track metrics like:

– Reduction in electrical-related incidents.

– Fewer near-miss reports.

– Better compliance audit scores.

– Reduced lighting-related complaints or errors.

Wrapping It Up

Safe workplaces aren’t built on luck. They’re built on systems, well-lit spaces, up-to-code wiring, trained people, and a culture that refuses to cut corners.

If you want a place where people can do their jobs without unnecessary risk, start with the basics, make sure your electrical systems are safe, and your lighting is done with intention.

And yes, sometimes that means hiring top electrical contractors instead of settling for whoever’s cheapest. The difference might not be obvious tomorrow, but it could be the reason everyone goes home safe next year.