Managing debris efficiently and safely on construction sites is essential for productivity, cost control, and regulatory compliance. One of the most effective tools that construction professionals use to streamline waste management is heavy-duty construction trash chute solutions. These systems help move construction waste safely from elevated floors to disposal areas, improving jobsite safety and efficiency while reducing labor and cleanup costs.

This comprehensive guide offers detailed insights, practical tips, and expert knowledge to help contractors, project managers, and site supervisors maximize the benefits of heavy-duty construction trash chute solutions.

The article covers the types and benefits of chutes, installation and maintenance best practices, safety and compliance requirements, troubleshooting tips, and specialized applications that help meet the complex demands of modern construction projects.

For industry-leading heavy-duty construction trash chute systems designed to deliver durability, reliability, and safety, visit HodChutes Trash Chutes.

What Are Heavy-Duty Construction Trash Chute Solutions?

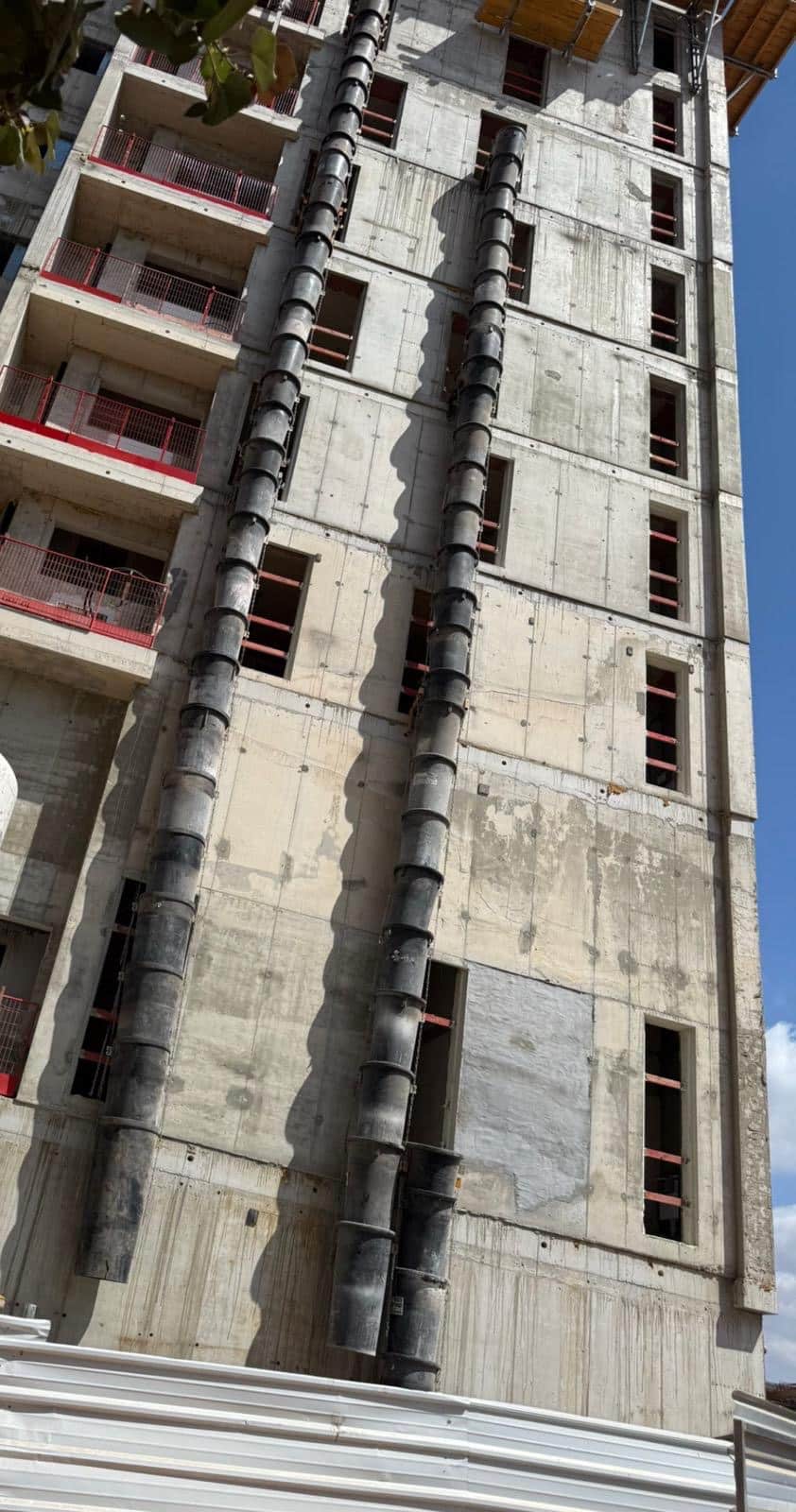

Heavy-duty construction trash chute solutions are modular vertical systems engineered to transport heavy and abrasive construction waste like concrete, bricks, roofing shingles, drywall, metal scraps, and wood chips safely and efficiently from upper-story worksites to ground-level containers or dumpsters.

Constructed primarily from durable materials such as UV-resistant high-density polyethylene (HDPE) plastics and reinforced steel, heavy-duty chutes are capable of withstanding frequent, rigorous impacts and harsh weather conditions without compromising safety or performance.

Their modular design allows for rapid assembly and disassembly suited to buildings of varying heights and scaffolding configurations, offering flexibility for use in multi-story demolition, renovation, roofing, and restoration projects.

Benefits of Heavy-Duty Construction Trash Chute Systems

Increased Operational Efficiency

Heavy-duty trash chutes allow workers to dispose of debris immediately without manual hauling down stairs or ladders, markedly reducing labor time and accelerating cleanup. The continuous vertical waste transport system eliminates workflow bottlenecks, helping projects stay on or ahead of schedule.

Enhanced Site Safety

By confining heavy and potentially hazardous debris within a secure chute, heavy-duty systems dramatically reduce the risk of injury due to falling objects. They also minimize physical strain and the accident risk involved in manual waste handling—leading to fewer worker injuries and improved site morale.

Regulatory Compliance

Trash chutes help contractors meet OSHA requirements and environmental regulations by controlling dust and debris emissions and reducing noise pollution. They maintain cleaner sites that are easier to inspect and comply with waste management best practices.

Cost Savings and ROI

Though the initial investment in heavy-duty chutes may be higher than basic systems, these units offer significant long-term value by reducing labor costs, obviating frequent replacement, limiting injury-related expenses, and preventing regulatory fines and project delays.

Types of Heavy-Duty Construction Trash Chute Solutions

Plastic Heavy-Duty Chutes

Made primarily from impact- and UV-resistant HDPE, plastic heavy-duty chutes offer a balance of durability and portability. They are corrosion-proof, lightweight, and ideal for roofing debris, drywall, and general construction waste. Their modular sections enable quick installation and disassembly.

Steel Construction Trash Chutes

Steel chutes are the preferred choice for demanding demolition projects. Fabricated from coated steel to withstand rugged debris like concrete slabs and metal scrap, these chutes ensure longevity under severe working conditions and heavy use.

Modular Trash Chute Systems

The modular approach uses stackable and lockable chute sections, allowing for customizable lengths and adaptability to complex site requirements. This system supports easy transportation, storage, and scalability according to project size and duration.

Electric Winch-Equipped Systems

For multi-story projects, electric winches allow safe and efficient raising or lowering of long, heavy chute sections, reducing labor intensity, and improving installation speed and worker safety on tall buildings.

Plastic vs. Steel Chutes: Which Is Better?

While some contractors use heavy steel chutes, plastic chutes are the preferred choice for roofing, demolition, and multi-story projects due to their portability and cost savings. Plastic chutes are significantly lighter, easier to install, and safer to handle, reducing the physical strain on labor crews. They require less maintenance, are corrosion-resistant, and ship faster than steel chutes, making them a cost-effective alternative.

Steel chutes do provide unmatched durability and are often chosen for projects requiring maximum fire resistance or involving exceptionally heavy debris loads. However, their weight and complexity make them harder to manage, increasing installation time and labor costs.

Plastic chutes offer a balanced solution for most construction and demolition needs, combining strength with flexibility, safety, and ease of use.

Key Features and Materials

- High-density polyethylene (HDPE): Provides excellent impact resistance, UV protection, and chemical inertness.

- Reinforced steel hardware: Durable mounting chains, clamps, and bolts improve safety.

- Anti-vibration mounts: Reduce noise and mechanical stress.

- Ergonomic wide hoppers: Allow rapid debris loading while minimizing spillage.

- Dust control components: Self-closing gates and sealable sections control particulate release.

Installation Best Practices

- Site Evaluation: Identify secure scaffold, balcony, or roof attachment points capable of safely supporting chute weight and dynamic waste loads.

- Use Certified Hardware: Employ steel chains, brackets, and fasteners conforming to code and manufacturer specifications.

- Modular Assembly: Ensure tight connections between chute sections to prevent gaps, leaks, or detachment.

- Secure Container Attachments: Fix dumpster bags or bins firmly to the chute outlet to avoid debris spillage.

- Electric Winch Assistance: Use mechanized lifting for safer, faster setup, especially on high rises.

- Safety Inspections: Maintain regular inspections and train crews on proper chute loading, weight limits, and emergency procedures.

Maintenance Tips for Longevity and Safety

- Conduct daily visual inspections for cracks, hardware loosening, and corrosion.

- Clean debris and dust buildup regularly using non-abrasive detergents and high-pressure water.

- Apply deodorizing and disinfecting treatments to reduce odors and microbial growth.

- Promptly replace worn or damaged chute sections and hardware.

- Store sections indoors protecting against weathering to extend service life.

- Keep a clear maintenance log and schedule periodic professional assessments.

Safety Standards and Compliance

Heavy-duty chutes must adhere to OSHA regulations and local building codes. They require guardrails at opening points, clear signage of load limits, and self-closing access doors. Landing zones must be clear and marked, and workers trained thoroughly on chute usage and hazards.

Troubleshooting Common Issues

- Blockages: Often caused by oversize or wet debris; quickly halt use and clear blockages with designated tools or manual removal.

- Hardware Damage: Immediately tighten or replace weak chains, bolts, or clamps.

- Dust Leaks: Inspect and supplement gaskets, hoods, and seals as needed.

- Noise Complaints: Install vibration-reducing mounts or noise-damping barriers.

Specialized Applications

Roofing Debris Chutes

Constructed with abrasion-resistant materials able to handle granulated roofing shingles and ceramic tiles. Wider hoppers improve loading speed during roofing tear-offs.

Demolition Chutes

Steel or reinforced composite chutes designed for heavy, abrasive demolition debris deliver unmatched durability and safety.

Interior Renovations

Lightweight, modular plastic chutes configured for indoor use minimize dust and noise while ensuring safe waste removal.

Frequently Asked Questions (FAQs)

What loading capacity can heavy-duty chutes handle?

Depending on design and materials, they can withstand hundreds of pounds per load and continuous heavy use.

Can chutes be customized to fit unique job sites?

Yes, modular design allows adaptation to complex scaffold layouts and variable building heights.

How does electric winch integration improve safety?

It automates heavy lifting, reducing manual labor risks and speeding installation.

What are the cleaning best practices?

Regular sweeping, high-pressure washing, and disinfecting prevent buildup and odors.

Case Study: Heavy-Duty Trash Chute System Saves Time and Improves Safety in Multi-Story Demolition

In a 20-story building demolition, switching to a steel modular chute system equipped with an electric winch reduced cleanup time by 40%, lowered injury rates, and met strict environmental requirements. The durability and dust control features were fundamental to project success and community relations.

Environmental Advantages and Compliance

Efficient waste containment through trash chutes minimizes air dust and site spillage, improving local environmental health and supporting green building certifications such as LEED and WELL.

Advanced Tips to Maximize Efficiency with Heavy-Duty Construction Trash Chutes

Optimize Chute Placement Strategically

Location of chute placement significantly impacts workflow efficiency and safety. Ideally, chutes should be positioned where they minimize debris travel distance on upper floors while providing straightforward paths to dumpster areas. Avoid placing chutes near high-traffic walkways or entrances to reduce interference with daily operations and pedestrian flow.

Using multiple chutes on large or complex sites can improve sorting and disposal efficiency. For example, dedicate specific chutes for roofing debris, heavy demolition scrap, or recycling materials where feasible.

Use Dumpster Bags Compatible with Chute Systems

Pairing your heavy-duty construction trash chute solution with high-quality dumpster bags designed for compatibility optimizes debris containment and transfer. These bags secure neatly around chute exits, preventing mid-drop debris scatter and overflowing hazards.

Choosing reinforced, tear-resistant bags suitable for heavy construction waste enhances environmental protection and reduces cleanup needs around dumpster sites.

Implement Loading Protocols and Monitoring

Establish clear protocols for workers on how and when to load debris into chutes. Limiting the size and weight of dropped materials prevents jams and excessive chute wear. Employ supervisors or designated waste-handling personnel to monitor loading practices actively and address safety infractions promptly. Technology-enabled monitoring tools like chute cameras or pressure sensors can offer real-time feedback on chute usage and identify blockages early, saving project time.

Integrate Dust Suppression Systems

Construction dust poses health risks and causes compliance issues. Integrate dust control attachments or misting systems near shake gates or hopper openings to suppress airborne particles during debris loading. Coupling these with the natural dust-controlling features of enclosed chute design elevates site cleanliness, especially during dry or windy conditions.

Schedule Preventive Maintenance Checks

- Besides daily visual checks, schedule monthly detailed inspections by trained maintenance staff. These checks should include:

- Measuring chain tension and wear rates

- Testing self-closing gates functionality and seal integrity

- Inspecting electric winch operations and safety cutoffs

- Reviewing documentation for any incident reports regarding the chute system

Maintaining a detailed log of maintenance activities ensures accountability and helps predict future repair needs.

Innovations in Heavy-Duty Trash Chute Technology

Smart Material Choices

Recent advancements in polymer science have led to composite chute sections combining toughness, flexibility, and lightweight properties. These materials absorb impact more effectively than traditional plastics and steel while resisting environmental degradation, ultimately extending chute life and reducing maintenance.

Modular Adaptability with Quick Connect Systems

Innovative quick-connect mechanisms enable faster setup and breakdown of chute systems with minimal tools—important for fast-paced construction timelines needing frequent chute repositioning. These systems maintain full structural strength while increasing workforce productivity.

Enhanced Electric Winch Systems

Modern electric winches incorporate sensor feedback, auto-lock features, and remote controls to allow precise, hands-free chute manipulation with increased safety margins. Integration with site-wide monitoring software enables project managers to track installations remotely and coordinate logistics efficiently.

IoT and Smart Monitoring

Some heavy-duty waste chute manufacturers now embed sensors within chute systems to monitor real-time usage metrics like material flow velocity, impact forces, and section integrity. This data supports predictive maintenance, preventing costly unscheduled downtime by forecasting part wear or blockages.

Market Trends and Industry Outlook

Construction growth forecasts and rising regulations globally are increasing demand for advanced trash chute solutions. The market is shifting towards modular, multi-functional, and environmentally-friendly systems compatible with sustainable construction practices.

The integration of technology and materials science continues to drive the industry towards safer, smarter, and more cost-efficient solutions—making investments in premium heavy-duty construction trash chute solutions a prudent decision for contractors focused on future-proofing their operations.

Practical Examples of Heavy-Duty Trash Chute Application

Large-Scale Commercial Renovation

A commercial renovation project exceeding 100,000 square feet utilized modular HDPE chutes to handle drywall, wood, and metal scraps from multiple floors simultaneously. Installation of electric winch systems reduced chute segment repositioning time by over 50%, dramatically improving debris clearance rates and minimizing project downtime.

High-Rise Demolition

In a downtown high-rise demolition, reinforced steel chutes equipped with impact-absorbing liners effectively transported heavy masonry and concrete debris. The robust construction withstood daily heavy use over a three-month period without replacement, proving the cost-efficiency of investing in quality materials upfront.

Residential Roofing Replacement

A roofing contractor chose lightweight plastic roofing chutes with abrasion-resistant liners for shingle teardown. The modular design allowed quick assembly on narrow building rooftops, while dust hoods reduced particulate emissions, aiding community relations in a dense neighborhood setting.

Strategic Benefits of Investing in Premium Trash Chute Solutions

- Reduced Project Risk: Minimized accidents and compliance violations reduce reputation damage and costly legal issues.

- Improved Team Morale: Safer, cleaner sites foster better working conditions, reducing absenteeism and turnover.

- Enhanced Client Satisfaction: Faster, safer debris removal accelerates project delivery and enhances client trust.

- Sustainability Credentials: Environmentally responsible waste containment supports green building certifications and corporate social responsibility goals.

Conclusion

Heavy-duty construction trash chute solutions are indispensable components in modern, efficient, and safe construction operations. Their ability to streamline debris removal, enhance worker safety, support regulatory compliance, and provide strong financial returns makes them a powerful investment.

By selecting innovative, durable, and customizable chute systems and implementing best practices in installation, maintenance, and operation, construction professionals can effectively meet the rigorous demands of today’s construction environments.

When choosing your next heavy-duty construction trash chute solution, consider the market leader known for quality and customer support: explore HodChutes Trash Chutes, your trusted partner in excellence.