Ever stare at a furniture tag and wonder what “manufactured wood” actually means?

You’re not alone. Walk into any furniture store, and those confusing terms pop up everywhere. “Engineered wood.” “Composite materials.” “MDF construction.”

It feels like shopping in a foreign language sometimes.

Here’s the thing: these materials are everywhere in your home. That bookshelf in your living room? Probably made from it. Your kitchen cabinets? Very likely.

But don’t worry. It’s not as complicated as it sounds.

This guide breaks down everything in simple terms. No confusing jargon. No overwhelming technical details. Just the facts you need to make smart buying decisions.

Understanding Manufactured Wood

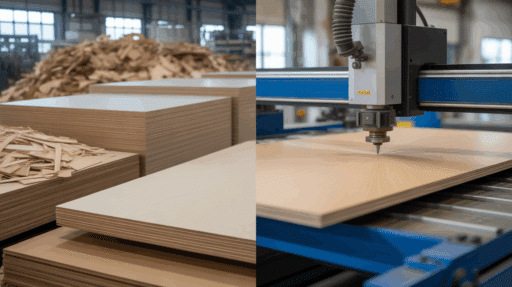

Manufactured wood refers to wood products created by combining wood fibers, particles, veneers, or strands with adhesives and binding agents.

These materials are processed under heat and pressure to create stable, uniform panels and boards.

The key difference from solid wood is that manufactured wood uses smaller wood pieces or fibers that are reassembled, rather than being cut directly from a tree trunk.

This engineered approach allows manufacturers to create consistent products with predictable performance characteristics, reducing waste from natural wood defects.

Many manufactured wood products also offer improved dimensional stability compared to solid wood, making them less prone to warping, splitting, or seasonal movement.

Types of Manufactured Wood Products

Think of manufactured wood like a family tree. Each type has its personality and best uses.

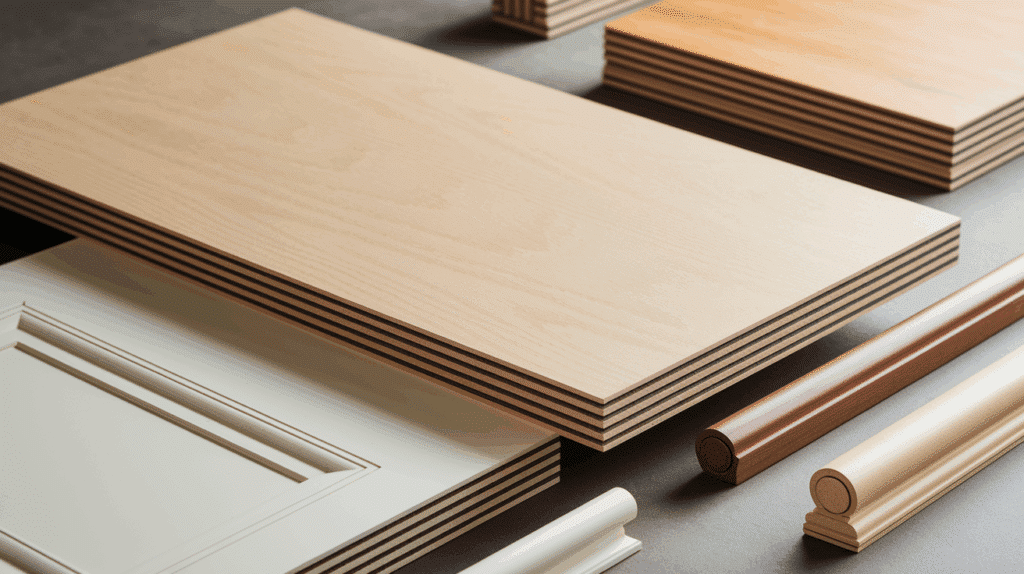

1. Medium Density Fiberboard (MDF)

MDF is like the friendly neighbor of manufactured wood. It’s smooth as silk and takes paint better than almost anything else. Perfect for painted furniture projects and budget makeovers.

Construction: Fine wood fibers mixed with resin and wax

Characteristics: Smooth surface, easy to paint, consistent density

Typical uses: Cabinet doors, furniture backs, decorative molding

2. Particleboard (Chipboard)

This is the starter option for many furniture pieces. Think of it as the training wheels of wood products. Great for light-duty jobs, but not ideal for heavy books or dishes.

Construction: Wood chips and particles bonded with adhesive

Characteristics: Lightweight, economical, less intense than MDF

Typical uses: Shelving, furniture substrates, underlayment

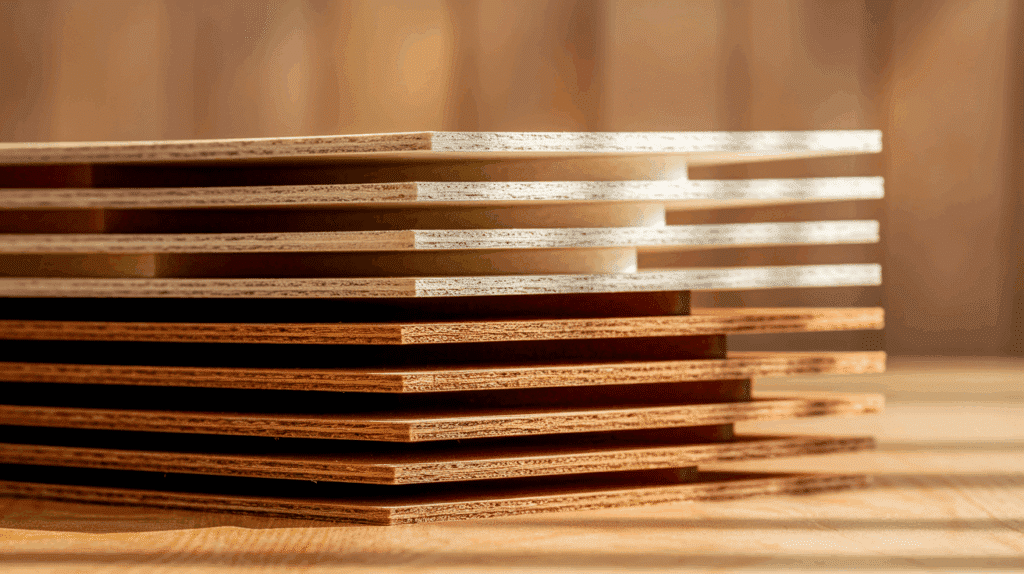

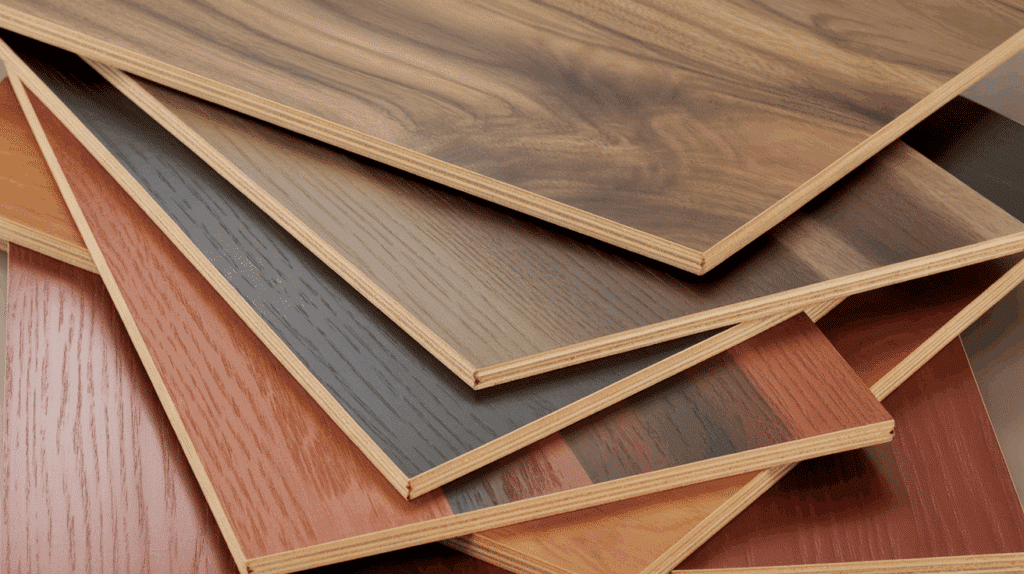

3. Plywood

Plywood is the overachiever of the group. Those criss-crossed layers make it super strong and stable. It’s been around forever because it simply works well for serious projects

Construction: Thin wood veneer layers glued in alternating grain directions

Characteristics: Strong, stable, available in various grades

Typical uses: Cabinets, flooring, structural applications

4. High-Density Fiberboard (HDF)

Think of HDF as MDF’s tougher big brother. It handles moisture better and stands up to daily wear and tear. You’ll find it under most laminate floors because it’s built to last.

Construction: Similar to MDF but denser and stronger

Characteristics: Hard surface, moisture resistant, stable

Typical uses: Laminate flooring, high-wear surfaces

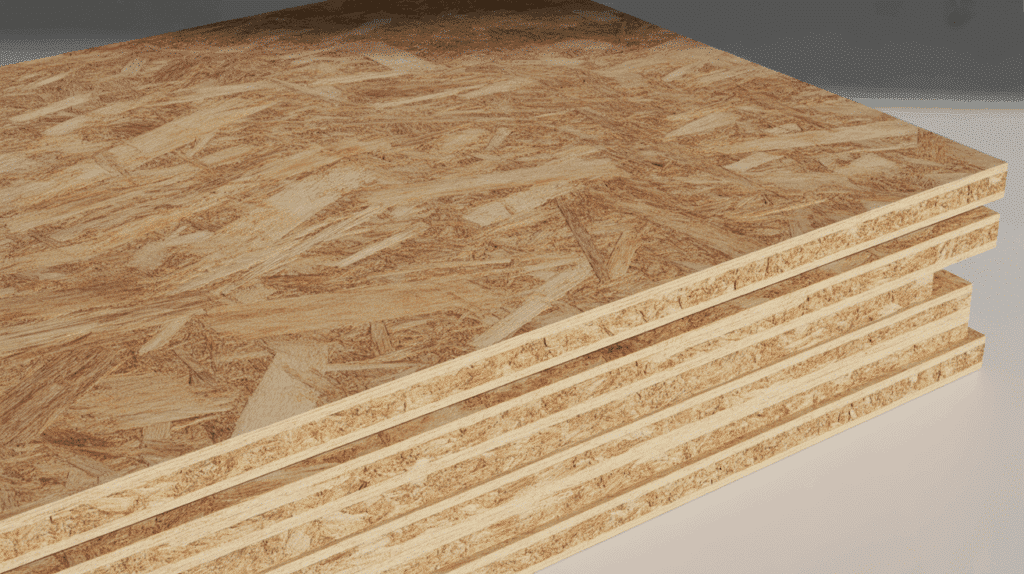

5. Oriented Strand Board (OSB)

OSB looks a bit rough around the edges with its visible wood chips. But don’t let looks fool you – it’s plenty strong for construction work. Builders love it because it delivers strength without breaking the budget.

Construction: Wood strands arranged in specific orientations

Characteristics: Strong, economical, visible strand pattern

Typical uses: Structural sheathing, subflooring

Quick Comparison Table

Sometimes you just need the facts at a glance. This table breaks down the key differences without all the fluff. Use it to quickly compare your options when shopping.

| Material | Strength | Moisture Resistance | Paint-ability | Cost |

|---|---|---|---|---|

| MDF | Medium | Low | Excellent | Low |

| Particleboard | Low | Very Low | Good | Very Low |

| Plywood | High | Medium-High | Good | Medium-High |

| HDF | High | Medium | Good | Medium |

| OSB | High | Low-Medium | Fair | Low-Medium |

Why Manufacturers Choose Engineered Wood

Using wood scraps and smaller pieces reduces waste and material costs, making furniture more affordable for consumers.

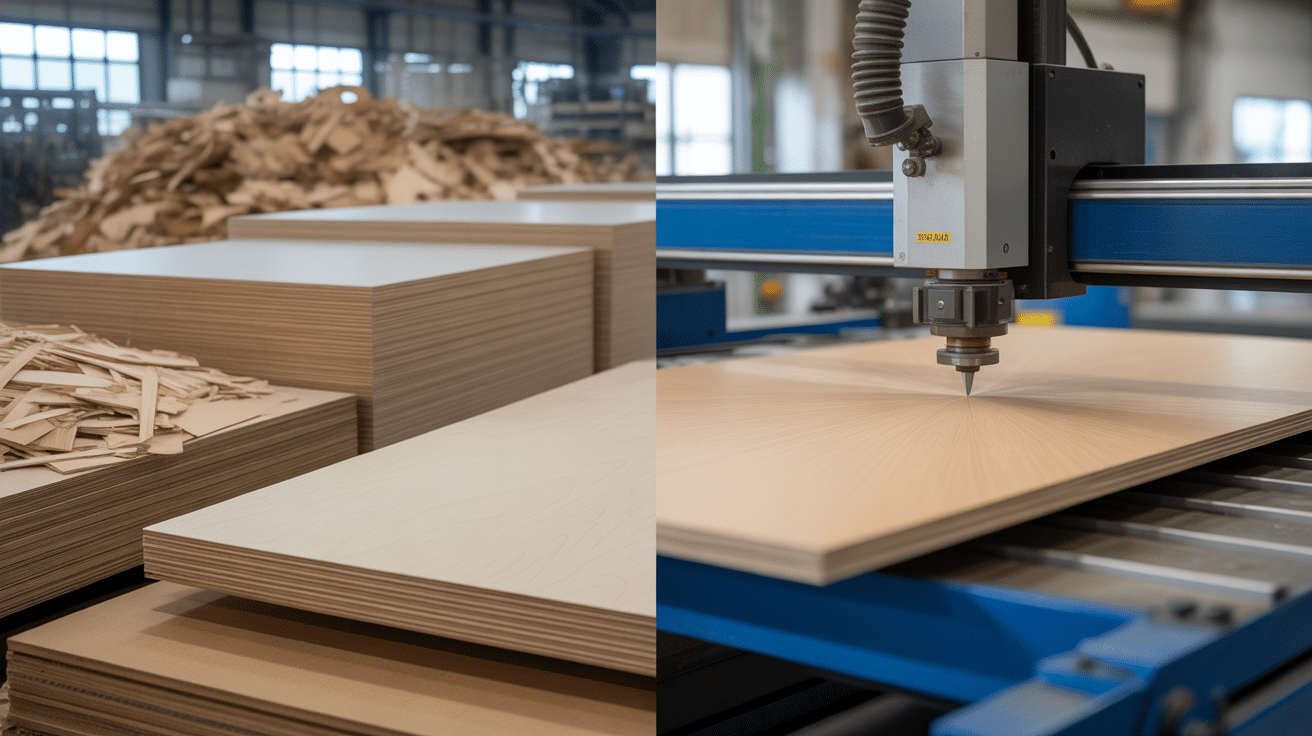

Unlike solid wood, manufactured products have uniform density and properties throughout, eliminating natural variations like knots or grain irregularities.

These products resist warping, shrinking, and expanding better than solid wood, especially in varying humidity conditions.

Manufactured wood cuts, drills, and shapes predictably, allowing for precise manufacturing and assembly.

Manufactured vs. Solid Wood

Choosing between manufactured and solid wood depends on your needs, budget, and expectations for durability and aesthetics. Each has its strengths and limitations, and knowing the key differences can help you make informed decisions.

| Category | Manufactured Wood | Solid Wood |

|---|---|---|

| Strength and Durability | – Consistent strength throughout – Vulnerable to moisture damage – Can chip or dent more easily – Limited repair options | – Natural strength varies by species – Better moisture resistance – Can be sanded and refinished multiple times – Develops character over time |

| Aesthetics and Appearance | – Uniform appearance – Often covered with veneer or laminate – Paint adheres well – No natural wood grain (unless veneered) | – Natural grain patterns and character – Can be stained to highlight grain – Ages and patinas naturally – Unique appearance in every piece |

| Cost Considerations | – Lower initial cost – Replacement rather than repair – Good value for temporary or budget furniture | – Higher upfront investment – Long-term value retention – Can be restored and refinished |

When to Choose Manufactured Wood

Ideal situations for manufactured wood:

- Budget-conscious purchases – Get the look you want without the premium price

- Temporary or transitional furniture – Perfect for apartments, dorms, or starter homes

- Children’s furniture – Replaceable and safe for growing kids

- Painted finishes – MDF provides the smoothest paint surface

- Consistent climate environments – Indoor use where humidity is controlled

Best applications:

- Bookshelves and storage units

- Cabinet doors and face frames

- Furniture backs and interior components

- Decorative elements and trim work

When Solid Wood Is Worth the Investment

Choose solid wood for:

- Heirloom pieces – Furniture intended to last generations

- High-use items – Dining tables, desks, bed frames

- Outdoor applications – Decks, outdoor furniture (with proper species selection)

- Structural elements – Load-bearing components

- Natural finish preferences – When you want to showcase wood grain

Fact Check: Common Misconceptions

Even though manufactured wood is widely used, several misconceptions still linger. Let’s separate myth from fact so you can make informed choices when evaluating furniture or building materials:

| Myth | Truth |

|---|---|

| Manufactured wood isn’t real wood. | It’s made from real wood fibers and particles, just processed differently. |

| All manufactured wood is of low quality. | Quality varies widely; high-grade plywood can outperform some solid woods. |

| Manufactured wood always off-gases harmful chemicals. | Modern products often meet strict emission standards; look for CARB Phase 2 or GREENGUARD certification. |

| You can’t repair manufactured wood. | While options are limited, minor damage can often be fixed with wood filler and touch-up materials. |

Environmental Considerations

Manufactured wood sits at the center of many eco debates. But the truth isn’t black and white. Like most things in life, there are good points and not-so-good points. Let’s look at both sides fairly.

The Positive Side

- Resource efficiency: Uses wood scraps and fast-growing species

- Forest conservation: Reduces demand for old-growth timber

- Waste reduction: Incorporates wood industry byproducts

Eco-Friendly Shopping Tips

- Look for FSC (Forest Stewardship Council) certification

- Choose CARB Phase 2-compliant products for lower emissions

- Consider GREENGUARD-certified options for indoor air quality

- Support manufacturers with transparent sustainability practices

Key takeaway: Look for certified low-emission products like CARB Phase 2 or GREENGUARD Gold, and always buy with long-term use in mind.

Real User Experiences

Budget Success Story: “I furnished my first apartment entirely with manufactured wood furniture. Three years later, it still looks great and cost me a fraction of solid wood prices. Perfect for getting started!” – Sarah, 26

Mixed Results: “My MDF bookshelf works great indoors, but the particleboard dresser started sagging after two years of heavy use. You get what you pay for.” – Mike, 34

Professional Perspective: “As a cabinet maker, I use both. Solid wood for face frames and doors, plywood for boxes, and MDF for painted elements. Each material has its place.” – Linda, Master Craftsperson.

The Bottom Line

Manufactured wood products offer practical solutions for many furniture and construction needs. They’re not inferior to solid wood – they’re different, with their advantages and appropriate applications.

Choose manufactured wood when you need cost-effective, stable, paint-ready materials for controlled indoor environments.

Choose solid wood when you’re making a long-term investment in pieces that will see heavy use or need periodic refinishing.

The best choice depends on matching the material properties to your specific needs, lifestyle, and budget. Both have their place in modern homes and construction.

What’s your experience with manufactured wood products? Share your thoughts and questions in the comments below!