Choosing the right water transfer pump requires more than a quick purchase decision. The process depends on understanding the specific job, the type of liquid, and the conditions the pump will face. Asking the right questions before buying helps avoid costly mistakes and leads to a pump that performs well for years.

Each application has its own needs, whether it involves moving clean water, handling waste, or supporting farm or construction work. By thinking through key factors such as flow rate, pressure, power source, and site conditions, anyone can make a confident and informed choice.

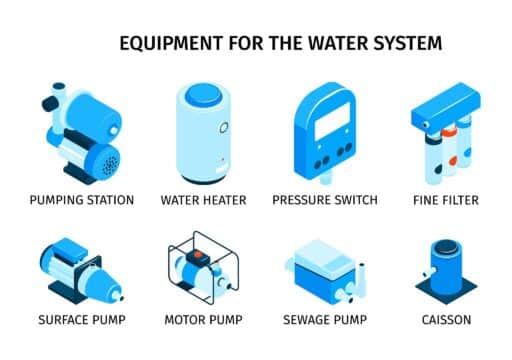

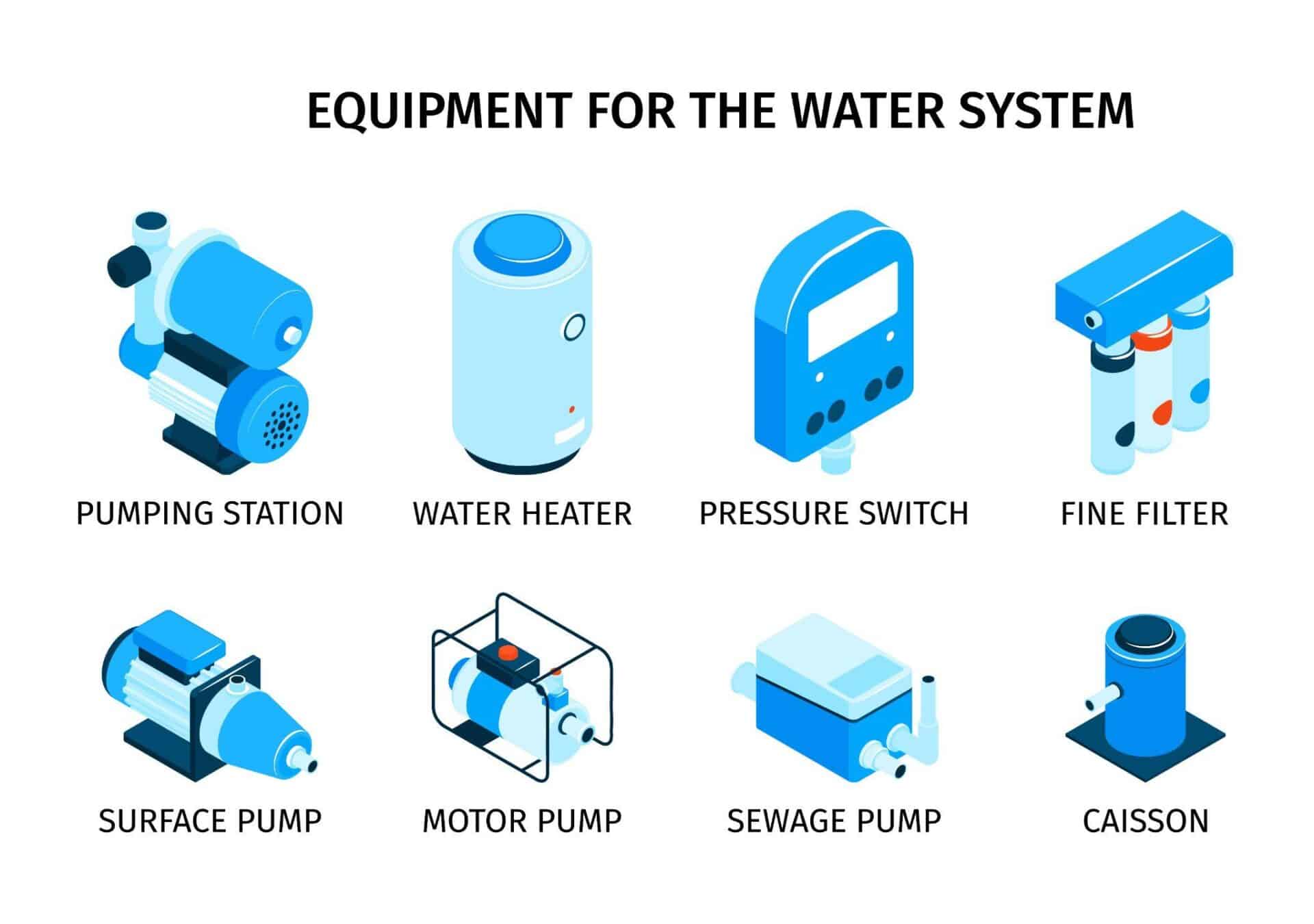

What type of fluid will you be pumping?

The type of fluid plays a major role in selecting the right pump. Water, fuel, and slurry each have different properties that affect how a pump performs. A pump that suits clear water may not handle thick or abrasive liquids well.

Buyers should know the fluid’s viscosity, temperature, and presence of solids before choosing a model. For example, clean water requires less pressure and filtration than dirty or sandy water. Fluids with debris or chemicals may need corrosion-resistant materials or a stronger impeller design.

Selecting a pump that suits the fluid type helps prevent damage, reduces maintenance, and improves performance. This step also extends the pump’s life and supports consistent flow for the intended application.

What is the required flow rate and pressure?

Flow rate and pressure decide how well a water transfer pumps perform. Flow rate refers to how much water the pump can move in a set time, usually measured in litres per minute. Pressure measures the force that pushes the water through pipes or hoses. Both must match the job’s needs for the pump to work effectively.

A user should first estimate how much water the system must move. For example, a large tank or multiple outlets need a higher flow rate. However, small household tasks may only need a modest amount of water movement.

Pressure depends on the distance and height the pump must move water. A pump that pushes water uphill or across long distances must produce greater pressure. If pressure is too low, water may not reach all outlets evenly.

It helps to check both flow rate and pressure specifications together. A balanced setup prevents strain on the pump and maintains consistent performance across the system.

Is the pump compatible with your power source?

A buyer should confirm that the pump matches the available power supply before purchase. Some pumps use single-phase electricity, while others need a three-phase setup. A mismatch can cause poor performance or damage to the motor.

Power availability often depends on the location. A remote site may rely on diesel or petrol engines, while a household or small workshop may use mains electricity. Therefore, the type of power source can influence which pump suits the job best.

It also helps to check the voltage and frequency requirements. Pumps designed for one region may not operate correctly in another without adjustment. This step prevents unnecessary downtime and extra costs.

In addition, buyers should consider energy efficiency and running costs. A pump that matches the power supply but consumes too much energy may not be practical in the long term. Choosing the right power match supports steady operation and helps extend the pump’s service life.

What are the environmental conditions of the installation site?

The conditions of the site affect how well a water transfer pump performs and how long it lasts. Soil type, temperature, and moisture levels can influence how the pump operates and how often it needs maintenance. A site with poor drainage or unstable ground may require extra preparation.

Local weather patterns also matter. Heavy rain, dust, or extreme heat can cause wear on equipment or affect water quality. Therefore, it helps to assess these factors before installation to avoid unexpected issues.

Nearby water sources and vegetation can also influence the setup. For example, a site close to a river or wetland may need measures to prevent contamination or erosion. Checking environmental regulations early can prevent delays and protect surrounding ecosystems.

Noise, vibration, and emissions should also be considered, especially in residential or environmentally sensitive areas. Careful planning helps reduce disturbance and supports compliance with environmental standards.

Do you need a portable or stationary pump?

A portable pump suits jobs that require movement between sites or quick setup in different areas. It works well for tasks such as draining water from tanks, small ponds, or temporary irrigation. Its lighter weight and compact frame make transport and storage easier.

A stationary pump fits projects that need continuous or long-term water transfer. It usually stays in one place and connects to fixed piping or power sources. This type often serves farms, construction sites, or facilities that move large volumes of water on a regular basis.

The choice depends on how often the pump must move and the scale of the work. A portable model offers flexibility and convenience, while a stationary unit provides steady output and durability. Buyers should assess the frequency of use, available space, and power supply before deciding which setup meets their needs best.

Conclusion

A clear set of questions helps buyers choose a pump that fits their needs. They should confirm the type of fluid, flow rate, and pressure requirements before purchase. These details guide the right match between the pump and the task.

Buyers should also check power source options, durability, and warranty terms. Each factor affects cost, performance, and maintenance over time.