Concrete garage floors often look similar at first glance, but what goes beneath the surface can shape how they hold up over time.

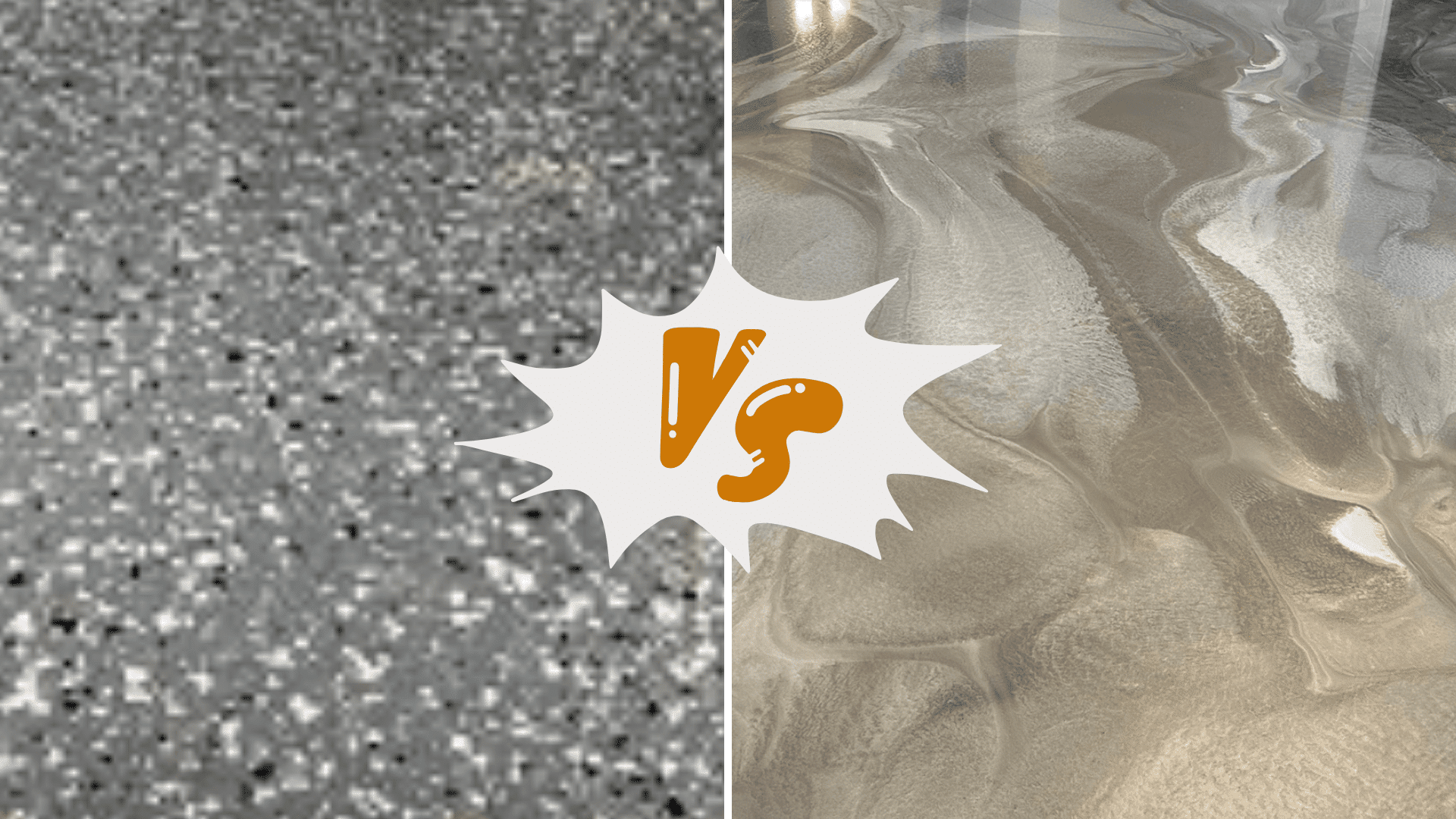

The debate around polyaspartic vs epoxy continues as homeowners weigh durability, cost, and long-term performance.

Both coatings promise protection, yet their behavior changes based on climate, usage, and installation conditions.

Choosing between them involves more than appearance or price alone. Key differences emerge in curing speed, surface flexibility, moisture response, and wear patterns.

Understanding how each option performs in real conditions helps clarify which coating fits specific needs.

What Is Polyaspartic Flooring?

Polyaspartic flooring is a high-performance concrete coating known for rapid curing and strong adhesion.

It is formulated from advanced polyurea chemistry, allowing installation within a single day.

The coating forms a flexible yet tough surface that resists cracking, staining, and surface wear.

Its low viscosity helps it penetrate concrete pores, improving bond strength.

Polyaspartic flooring also maintains color stability when exposed to sunlight, making it suitable for areas where appearance and long-term performance matter.

Polyaspartic Flooring Pros:

- Rapid curing allows same-day use

- Strong bond with concrete surfaces

- High resistance to UV exposure and staining

- Performs well across temperature variations

Polyaspartic Flooring Cons:

- Higher upfront installation cost

- Short working time limits design flexibility

- Requires experienced application for proper results

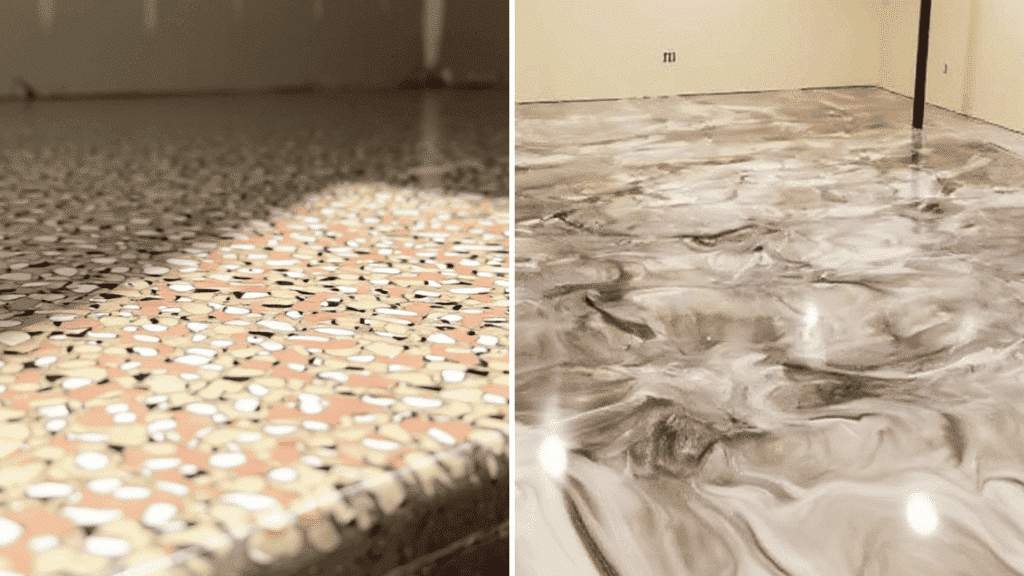

What Is Epoxy Flooring?

Epoxy flooring is a resin-based system created by combining epoxy resin with a hardening agent to form a rigid surface.

Once cured, it produces a thick, solid layer that shields concrete from impacts, chemicals, and heavy loads.

The material allows ample working time during installation, which supports decorative finishes and detailed surface preparation.

Epoxy flooring is commonly selected for controlled indoor environments where consistent temperatures and cost efficiency are key considerations.

Epoxy Flooring Pros:

- Lower material cost compared to alternatives

- Thick coating provides solid surface protection

- Suitable for decorative finishes and patterns

- Widely available and well-established option

Epoxy Flooring Cons:

- Longer curing time delays surface use

- Susceptible to discoloration from sunlight

- Less flexible under temperature changes

Key Differences Between Polyaspartic and Epoxy

This comparison highlights practical differences in application, performance, and suitability to help assess which coating aligns with specific project conditions:

| Feature | Polyaspartic Flooring | Epoxy Flooring |

|---|---|---|

| Curing Time | Sets within a few hours, allowing same-day use | Requires 24–72 hours before full use |

| Installation Speed | Completed quickly with minimal downtime | Takes longer due to extended curing |

| Durability | Handles impact, abrasion, and surface stress well | Provides a hard surface but may chip over time |

| UV Resistance | Maintains color when exposed to sunlight | May discolor when exposed to UV light |

| Temperature Range | Can be applied in hot or cold conditions | Needs controlled temperatures for best results |

| Moisture Tolerance | Bonds well even with minor concrete moisture | Sensitive to moisture during application |

Reviewing these distinctions makes it easier to weigh time constraints, environmental exposure, and budget priorities before selecting a concrete floor coating.

Which Coating Works Better for Specific Uses?

The right coating choice depends on how the space is used, environmental exposure, and turnaround expectations. Each option performs better in certain settings based on durability needs, appearance priorities, and installation timelines.

Below are common use-based scenarios:

- Garages: Polyaspartic flooring suits frequent vehicle traffic, temperature changes, and faster return to use.

- Basements: Epoxy flooring works well in enclosed areas with stable conditions and limited sunlight exposure.

- Commercial Spaces: Polyaspartic flooring supports high foot traffic and shorter downtime requirements.

- Workshops: Epoxy flooring provides a solid surface for equipment and detailed finishes.

Tip: Usage patterns and environmental conditions should be assessed before finalizing a coating to avoid premature wear or performance issues.

Cost and Maintenance Comparison

Pricing and upkeep differ based on coating type, surface condition, and project scope. While general cost ranges provide a useful reference, actual expenses can shift depending on installation complexity and usage demands.

Factors that affect overall cost:

- Concrete condition and preparation level

- Area size and layout complexity

- Coating thickness and finish type

- Traffic exposure and load requirements

- Local labor rates and scheduling constraints

Final pricing may vary based on several influencing elements.

| Cost Aspect | Polyaspartic Flooring | Epoxy Flooring |

|---|---|---|

| Material Price Range | Higher due to advanced formulation | Lower and more widely available |

| Labor Intensity | Requires faster, skilled application | Allows longer working time |

| Downtime Cost | Minimal due to quick return to service | Increased due to extended curing |

| Maintenance Frequency | Infrequent cleaning and repairs | Occasional surface touch-ups |

| Lifespan Value | Longer service life reduces repeat costs | Shorter lifespan may increase renewals |

Real-World Conditions of Polyaspartic vs Epoxy Flooring

When comparing polyaspartic vs epoxy garage floor performance, daily conditions play a major role in long-term results.

Garages face vehicle weight, tire heat, spills, and seasonal temperature changes.

Polyaspartic flooring handles these stresses with greater flexibility, helping the surface remain intact during expansion or contraction.

Epoxy flooring delivers a dense finish that supports heavy loads but performs best where conditions remain consistent.

Moisture presence during installation can also affect outcomes, as surface preparation requirements differ.

Light exposure, surface movement, and usage intensity further influence wear patterns over time.

Evaluating these real-world factors helps determine which coating aligns better with functional demands rather than appearance alone.

Polyaspartic vs Epoxy: Reddit Discussion

Discussions on public forums like Reddit highlight how real homeowners evaluate garage flooring based on climate, cost, and long-term use rather than product claims alone.

In colder regions, especially areas with snow, salt, and freeze–thaw cycles, users frequently share practical experiences comparing polyaspartic and epoxy systems.

Common observations shared by users include:

- Climate impact: Cold winters and moisture exposure tend to accelerate epoxy cracking and flaking over time.

- Salt and slush exposure: Standing meltwater and road salt are often cited as causes of surface wear on untreated or epoxy-coated floors.

- Curing expectations: Faster return to use is frequently mentioned as a reason for choosing polyaspartic coatings.

- Crack handling: Many users note that existing cracks and surface pitting influence coating success more than coating type alone.

- Cost awareness: Pricing transparency and square-foot estimates are recurring decision factors.

Overall, community feedback suggests that evaluating local conditions and slab condition plays a larger role in outcomes than brand or appearance alone.

Conclusion

Choosing between polyaspartic vs epoxy comes down to how a floor is expected to perform over time.

Polyaspartic flooring stands out for faster curing, flexibility, and better tolerance to changing conditions, while epoxy flooring remains a practical option for controlled spaces and tighter budgets.

Cost, maintenance expectations, surface condition, and local climate all play a role in how each coating holds up.

Real-world feedback shows that preparation and environment often matter as much as the coating itself.

When these factors are weighed together, the decision becomes clearer and more practical. Every garage or workspace has different demands, and the right choice reflects those needs.

Share your experience or preferred option below and let others know what worked best.

Frequently Asked Questions

Are Polyaspartic Garage Floors Worth It?

Polyaspartic garage floors are worth considering when quick installation, long-term durability, and resistance to temperature changes matter. They suit garages exposed to frequent vehicle use, moisture, and seasonal conditions better than basic coatings.

What is the Strongest Garage Floor Coating?

Strength depends on bonding, flexibility, and surface preparation. Polyurea-based systems, including polyaspartic coatings, are often considered among the strongest due to their ability to handle impact, abrasion, and surface movement.

Which is Better, Polyurea or Polyaspartic?

Polyurea offers extreme strength and fast curing but limited working time. Polyaspartic provides similar durability with improved control during installation, making it more suitable for residential garage floors.