Roofing decisions shape long-term building performance, not just appearance.

Metal roofing has gained steady attention because it addresses common concerns such as weather resistance, structural load, and replacement frequency.

However, metal roofing is not a single system; panel design, material choice, and installation method all influence results.

Without a clear breakdown, comparing options becomes difficult.

This article focuses on the seven most commonly chosen types of metal roofing and explains how each one functions, where it fits best, and what limitations to consider.

By the end, the differences become clear enough to support confident, practical roofing decisions.

What is Metal Roofing?

Metal roofing refers to roofing systems made from metal panels or shingles designed to protect buildings from weather exposure while offering long service life.

These systems are manufactured using materials such as steel, aluminum, copper, or zinc and are installed in various panel or shingle formats.

Why People Prefer Metal Roofing?

Metal roofing is used because it provides consistent performance, resists weather-related damage, and requires fewer replacements over time compared to many traditional roofing materials.

Its lightweight nature reduces structural load, while its design options allow use across residential, commercial, and agricultural buildings.

The combination of durability, efficiency, and adaptability makes metal roofing a practical choice across different climates and roof designs.

Types of Metal Roofing: Explained

Below are seven prominent types of metal roofing that I think are the best ones:

1. Standing Seam Metal Roofing

Standing seam metal roofing uses long vertical metal panels joined by raised seams that sit above the roof surface.

These seams keep water away from fasteners and reduce the risk of leaks.

The system relies on concealed clips instead of exposed screws, allowing the panels to move with temperature changes while maintaining a secure fit.

Standing seam roofs are commonly made from steel or aluminum and are widely used on residential and commercial buildings.

Best Use Case: Standing seam metal roofing suits buildings where long-term durability and reduced maintenance are prioritized over initial cost.

Pros of Standing Seam Metal Roofing

- Long service life with minimal maintenance needs

- Hidden fasteners reduce the chances of water penetration

- Performs well in heavy rain, snow, and wind

- A smooth surface allows snow and debris to slide off easily

- Works on low-slope and steep-slope roofs

Cons of Standing Seam Metal Roofing

- Higher material and installation costs compared to other metal roofs

- Installation requires skilled professionals

- Panel replacement can be difficult if damage occurs

- Not ideal for very small or complex roof shapes

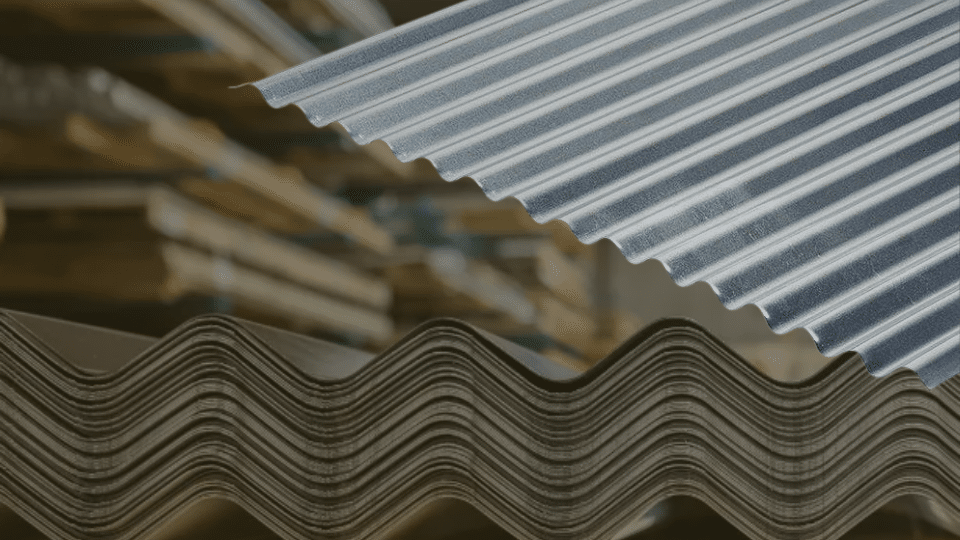

2. Corrugated Metal Roofing

Corrugated metal roofing is made from metal sheets shaped into repeating ridges or waves.

These panels are installed using exposed fasteners that secure the metal directly to the roof structure.

Corrugated roofing is commonly manufactured from steel or aluminum and is widely used due to its affordability and availability.

The ribbed design adds strength to the panels, allowing them to span larger areas with fewer supports.

While the system is simple, the exposed screws require regular inspection to prevent leaks over time.

Best Use Case: Corrugated metal roofing works well for sheds, garages, workshops, agricultural buildings, and cost-sensitive projects.

Pros of Corrugated Metal Roofing

- Lower material and installation cost

- Simple and quick installation process

- Strong panel design despite lighter weight

- Suitable for large roof areas

Cons of Corrugated Metal Roofing

- Exposed fasteners may loosen with time

- Requires periodic maintenance

- Shorter lifespan compared to concealed-fastener systems

- Industrial appearance may not suit all properties

3. Metal Shingle Roofing

Metal shingle roofing uses small interlocking metal panels designed to resemble traditional asphalt shingles, slate, or wood shakes.

These shingles are installed in overlapping rows, similar to standard shingle roofing, but provide better strength and weather resistance.

Metal shingles are often made from steel or aluminum and coated to resist corrosion.

They provide a familiar roof appearance while offering longer service life than asphalt-based options.

Best Use Case: Metal shingles suit residential homes where appearance matters, but improved durability is also required.

Pros of Metal Shingle Roofing

- Traditional roof appearance

- Better wind resistance than asphalt shingles

- Lighter weight than many conventional roofing materials

- Moderate maintenance requirements

Cons of Metal Shingle Roofing

- Higher cost than asphalt shingles

- Installation takes longer than panel systems

- Fewer style options compared to traditional shingles

4. Steel Roofing

Steel roofing is the most commonly used metal roofing material and is available in different forms, including standing seam, corrugated panels, and shingles.

It is usually coated with protective layers to reduce corrosion and extend its lifespan.

Steel offers a balance between strength, cost, and availability. It performs well in most climates when properly coated and maintained.

Best Use Case: Steel roofing fits homes and buildings that need reliable performance at a reasonable cost.

Pros of Steel Roofing

- Strong and impact-resistant

- Cost-effective compared to premium metals

- Available in many profiles and finishes

- Suitable for residential and commercial use

Cons of Steel Roofing

- Can corrode if the protective coating is damaged

- Heavier than aluminum

- Requires routine inspection in harsh climates

5. Aluminum Roofing

Aluminum roofing is valued for its natural resistance to corrosion.

It is commonly used in coastal or high-humidity environments where rust is a concern. Aluminum panels or shingles are lightweight and reflect heat effectively.

While aluminum performs well in wet conditions, it is softer than steel and may dent more easily under impact.

Best Use Case: Aluminum roofing is suitable for coastal homes or areas with frequent moisture exposure.

Pros of Aluminum Roofing

- Does not rust

- Lightweight material reduces structural load

- Suitable for coastal and humid regions

- Reflects heat efficiently

Cons of Aluminum Roofing

- Higher cost than steel

- More prone to denting

- Limited profile and color options

6. Copper Roofing

Copper roofing is a high-end metal roofing option known for its long service life.

It is often used on architectural features, historic buildings, or custom homes. Over time, copper develops a protective surface layer that reduces corrosion.

Copper requires little maintenance but comes with a high initial investment and specialized installation needs.

Pros of Copper Roofing

- Extremely long lifespan

- Naturally resistant to corrosion

- Minimal maintenance requirements

- Suitable for architectural detailing

Cons of Copper Roofing

- Very high material and installation costs

- Surface color changes over time

- Limited availability of experienced installers

Best Use Case: Copper roofing suits custom homes, historic structures, and buildings with long-term ownership plans.

7. Zinc Roofing

Zinc roofing systems are known for durability and long service life. The material forms a protective surface layer that helps reduce visible wear over time.

Zinc panels are often used in modern residential and commercial construction. Proper installation is critical, as zinc expands and contracts more than some other metals.

Best Use Case: Zinc roofing is suitable for high-end residential or commercial projects focused on longevity.

Pros of Zinc Roofing

- Long service life

- Low maintenance requirements

- Performs well in varied climates

- Surface damage may reduce over time

Cons of Zinc Roofing

- Premium pricing

- Requires skilled installation

- Limited availability in some regions

Other Metal Roofing Options Used for Specific Needs

Alongside the most widely used metal roofing systems, there are additional options designed to meet specific structural, functional, or design requirements.

These systems are less common but remain relevant for particular building conditions or visual preferences.

1. Stone-Coated Metal Roofing

This type uses a metal base panel that is permanently bonded with stone granules.

The coating adds surface texture, reduces glare, and helps limit rain noise compared to smooth metal panels. It is often chosen when a more traditional roof appearance is required without sacrificing metal roofing performance.

2. Ribbed Panel Roofing

Ribbed panel roofing features straight, pronounced ribs that run vertically along the panel surface.

These ribs increase structural strength, allowing the panels to span wider areas with fewer supports. The system is commonly used on utility buildings and projects that prioritize strength and efficient installation.

3. Flat Seam Metal Roofing

Flat seam systems use closely sealed seams that create a smooth, low-profile roof surface.

This type is mainly applied to low-slope roofs or buildings with architectural design requirements. Proper installation is critical to ensure water control and long-term performance.

4. Pressed metal tile panels

These panels are manufactured by shaping metal sheets into tile-like patterns.

They provide the visual appeal of traditional tile roofing while maintaining a lighter overall roof weight. This option is often selected when structural load limits rule out heavy tile materials.

How to Choose the Best Type of Metal Roofing for Your Home?

Selecting the right metal roofing type requires matching system performance to building conditions.

Review local climate patterns and moisture exposure

Consider the roof slope and framing support

Compare upfront costs with long-term upkeep

Confirm installation suitability and code requirements

Align roofing style with building function

A methodical evaluation prevents mismatched systems and supports long-term reliability.

Conclusion

Metal roofing offers structured solutions rather than one-size-fits-all answers.

The seven most widely used metal roofing types each serve distinct purposes, balancing cost, durability, and maintenance in different ways.

Panel systems prioritize weather control, shingle styles focus on familiar form, and premium metals support extended service life.

Understanding these differences reduces uncertainty and improves decision accuracy.

A well-chosen metal roofing system supports building protection for decades without frequent intervention.

Thoughts, questions, or experiences related to metal roofing choices are welcome; share them in the comments to keep the discussion useful and informed.