Threading a hole seems simple until the tap snaps halfway through.

The difference between clean threads and a ruined workpiece often comes down to one overlooked detail; the size of the hole you drilled first.

Too tight, and the tap binds. Too loose, and the threads won’t hold. That’s where a tap drill size chart becomes essential.

It’s not about guesswork or close-enough measurements. It’s about precision that prevents failure before it happens.

Metric threads, coarse standards, and fine-pitch applications all require different drill sizes to achieve accurate and secure threads.

One small number. One correct choice.

And suddenly, tapping becomes predictable instead of risky.

What Is a Tap Drill Size Chart?

A tap drill size chart shows which drill bit to use before threading a hole with a tap.

It pairs each tap size with the correct drill size, so the hole isn’t too tight or too loose.

This makes threading easier and keeps the tap from breaking or wearing out too fast.

The chart is used in metalworking, fabrication, and repair work where threaded holes are needed. It removes guesswork and keeps results consistent across multiple parts.

Following the chart means threads come out clean, fasteners fit correctly, and connections stay secure under load.

Whether working with steel, aluminum, or softer materials, using the right drill size from the start saves time and prevents costly mistakes during tapping.

How Tap Drill Sizes Are Calculated?

Tap drill sizes are calculated to balance thread strength with ease of tapping. The goal is to remove just enough material so threads can be formed cleanly without breaking the tap or weakening the hole.

The calculation mainly depends on how much of the thread profile is cut into the material and how the material reacts during tapping.

- ThreadPercentage Basics: Thread percentage shows how much of the thread is formed inside the hole. Lower percentages make tapping easier, while higher percentages create tighter threads.

- MaterialConsiderations: Material type affects drill size choice. Soffter materials handle tighter holes, while harder materials need slightly larger holes to reduce stress.

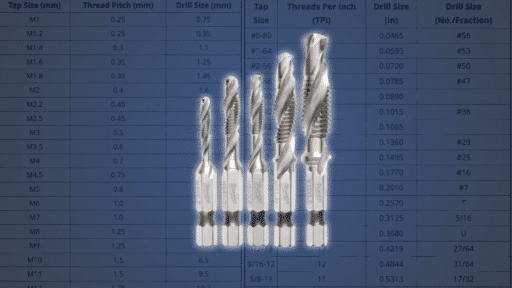

Tap Drill Size Chart

A standard tap drill size chart provides quick reference values for common tap sizes and matching drill bits.

These charts are organized by thread type and measurement system, helping ensure accurate hole sizing before tapping and reducing the risk of poor thread fit, tool wear, or material damage during the process.

Tap Drill Size Chart Metric Sizes

This table presents metric tap sizes alongside suitable drill diameters, helping maintain proper hole dimensions for consistent threading across various metric-based projects.

| Tap Size (mm) | Thread Pitch (mm) | Drill Size (mm) |

|---|---|---|

| M1 | 0.25 | 0.75 |

| M1.2 | 0.25 | 0.95 |

| M1.4 | 0.3 | 1.1 |

| M1.6 | 0.35 | 1.25 |

| M1.8 | 0.35 | 1.45 |

| M2 | 0.4 | 1.6 |

| M2.2 | 0.45 | 1.75 |

| M2.5 | 0.45 | 2.05 |

| M3 | 0.5 | 2.5 |

| M3.5 | 0.6 | 2.9 |

| M4 | 0.7 | 3.3 |

| M4.5 | 0.75 | 3.75 |

| M5 | 0.8 | 4.2 |

| M6 | 1.0 | 5.0 |

| M7 | 1.0 | 6.0 |

| M8 | 1.25 | 6.8 |

| M9 | 1.25 | 7.8 |

| M10 | 1.5 | 8.5 |

| M11 | 1.5 | 9.5 |

| M12 | 1.75 | 10.2 |

| M14 | 2.0 | 12.0 |

| M16 | 2.0 | 14.0 |

| M18 | 2.5 | 15.5 |

| M20 | 2.5 | 17.5 |

| M22 | 2.5 | 19.5 |

| M24 | 3.0 | 21.0 |

| M27 | 3.0 | 24.0 |

| M30 | 3.5 | 26.5 |

| M33 | 3.5 | 29.5 |

| M36 | 4.0 | 32.0 |

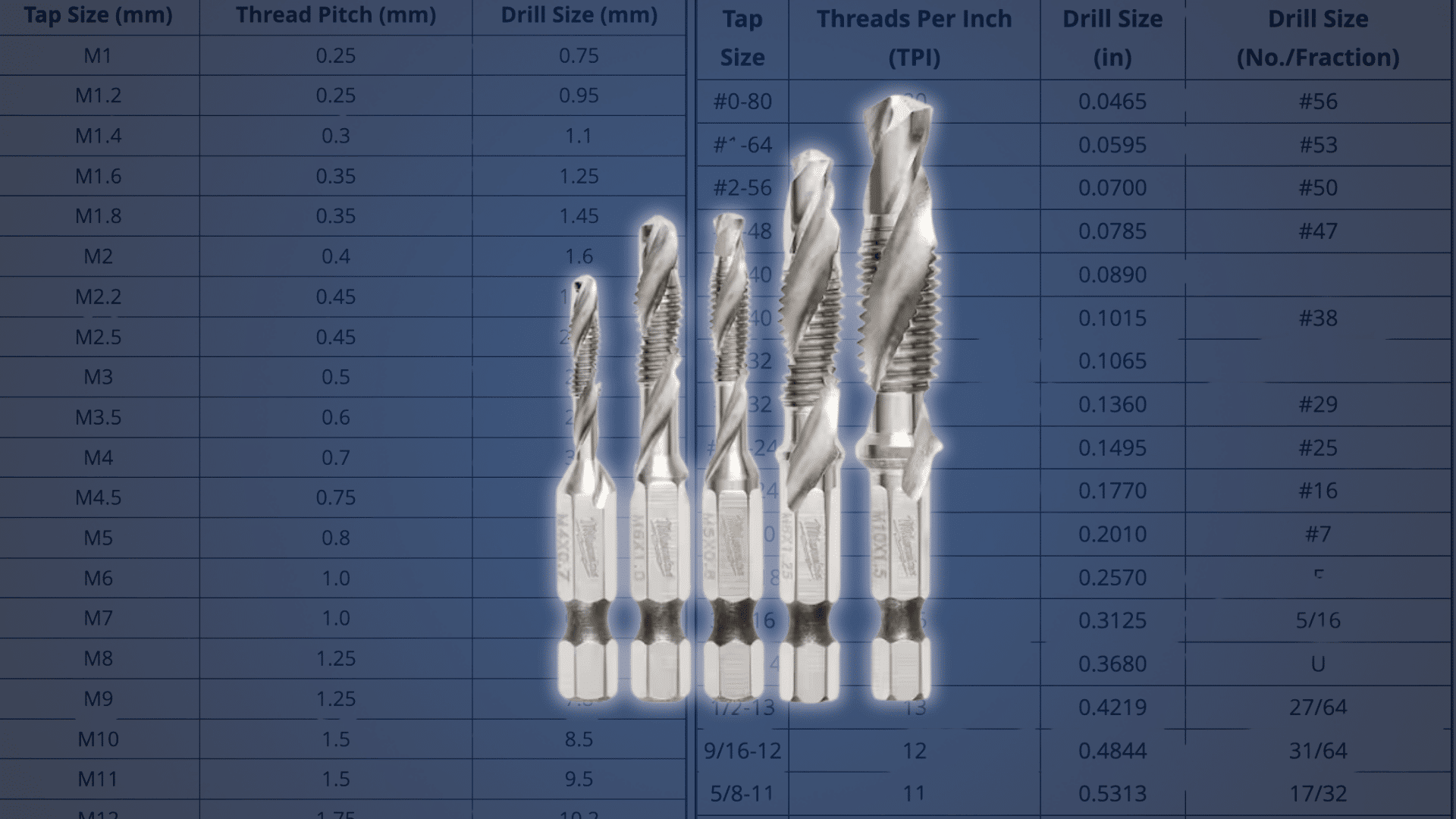

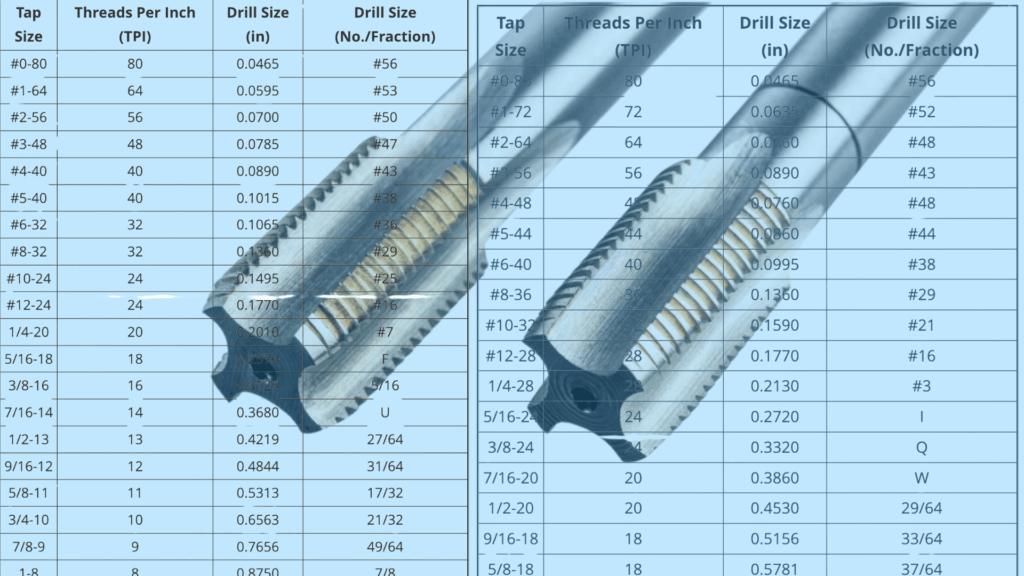

UNC (Unified National Coarse) Tap Drill Size Chart

This table outlines coarse-thread tap sizes with matching drill bits commonly used where faster engagement and standard fastening strength are required.

| Tap Size | Threads Per Inch (TPI) | Drill Size (in) | Drill Size (No./Fraction) |

|---|---|---|---|

| #0-80 | 80 | 0.0465 | #56 |

| #1-64 | 64 | 0.0595 | #53 |

| #2-56 | 56 | 0.0700 | #50 |

| #3-48 | 48 | 0.0785 | #47 |

| #4-40 | 40 | 0.0890 | #43 |

| #5-40 | 40 | 0.1015 | #38 |

| #6-32 | 32 | 0.1065 | #36 |

| #8-32 | 32 | 0.1360 | #29 |

| #10-24 | 24 | 0.1495 | #25 |

| #12-24 | 24 | 0.1770 | #16 |

| 1/4-20 | 20 | 0.2010 | #7 |

| 5/16-18 | 18 | 0.2570 | F |

| 3/8-16 | 16 | 0.3125 | 5/16 |

| 7/16-14 | 14 | 0.3680 | U |

| 1/2-13 | 13 | 0.4219 | 27/64 |

| 9/16-12 | 12 | 0.4844 | 31/64 |

| 5/8-11 | 11 | 0.5313 | 17/32 |

| 3/4-10 | 10 | 0.6563 | 21/32 |

| 7/8-9 | 9 | 0.7656 | 49/64 |

| 1-8 | 8 | 0.8750 | 7/8 |

UNF (Unified National Fine) Tap Drill Size Chart

This table lists fine-thread tap sizes and drill references designed for applications that require closer thread spacing and improved holding accuracy.

| Tap Size | Threads Per Inch (TPI) | Drill Size (in) | Drill Size (No./Fraction) |

|---|---|---|---|

| #0-80 | 80 | 0.0465 | #56 |

| #1-72 | 72 | 0.0635 | #52 |

| #2-64 | 64 | 0.0760 | #48 |

| #3-56 | 56 | 0.0890 | #43 |

| #4-48 | 48 | 0.0760 | #48 |

| #5-44 | 44 | 0.0860 | #44 |

| #6-40 | 40 | 0.0995 | #38 |

| #8-36 | 36 | 0.1360 | #29 |

| #10-32 | 32 | 0.1590 | #21 |

| #12-28 | 28 | 0.1770 | #16 |

| 1/4-28 | 28 | 0.2130 | #3 |

| 5/16-24 | 24 | 0.2720 | I |

| 3/8-24 | 24 | 0.3320 | Q |

| 7/16-20 | 20 | 0.3860 | W |

| 1/2-20 | 20 | 0.4530 | 29/64 |

| 9/16-18 | 18 | 0.5156 | 33/64 |

| 5/8-18 | 18 | 0.5781 | 37/64 |

| 3/4-16 | 16 | 0.6875 | 11/16 |

| 7/8-14 | 14 | 0.7969 | 51/64 |

| 1-12 | 12 | 0.8906 | 57/64 |

Using a standard chart helps maintain consistent drilling and tapping results across different projects, reduces sizing errors, and ensures threads fit fasteners properly while supporting reliable performance in both routine and precision work.

How to Use a Tap Drill Size Chart Correctly ?

A tap drill size chart is used by first identifying the tap size required for the fastener.

Once the tap size is known, the chart provides the matching drill bit size needed to prepare the hole before tapping begins.

After selecting the correct drill bit, the hole should be drilled straight and to the proper depth.

Clean holes allow the tap to cut threads evenly and reduce resistance.

Referring back to the chart before tapping helps confirm accuracy and supports consistent thread results across different materials and applications.

Common Tap Drill Size Mistakes to Avoid

Errors in tap drill sizing often lead to weak threads, broken taps, or poor fastener fit.

Many issues come from small oversights during drill selection, measuring, or preparation, which can affect thread quality even when the correct tap is used.

- Using approximate drill sizes

- Mixing metric and inch standards

- Skipping material checks

- Drilling uneven or shallow holes

Double-check the chart, tools, and measurements before drilling, as a few seconds of verification can prevent rework, tool damage, and thread failure later in the process.

Conclusion

A tap drill size chart isn’t just a reference; it’s damage prevention printed on paper. Get the drill size wrong, and you’re fighting broken taps, stripped threads, or fasteners that won’t hold.

Get it right, and threading becomes routine instead of stressful. The numbers matter. Thread percentage affects strength.

Material type changes requirements. Metric and imperial standards don’t mix.

And those common mistakes; approximate sizing, mismatched systems, skipped checks; they’re avoidable with a glance at the chart before you start drilling.

Steel, aluminum, softer materials; each responds differently to tapping, but accuracy beats speed every time.

The chart removes doubt. It keeps work consistent. And it saves more taps than most people realize.

What’s been your biggest tapping challenge? Share your experience or favorite tip below