In recent years, electric linear actuators have become an essential part of modern industrial automation. These compact, reliable devices make it possible to move, lift, tilt, push, or pull with precision — and they’re doing it in more industries than ever before. From smart factories to high-tech farming, the demand for automation is growing fast, and electric actuators are at the center of this shift.

At Progressive Automations, we’ve seen firsthand how these devices are reshaping machines and processes across sectors. As industries look for solutions that are cleaner, quieter, and easier to control, electric linear actuators are becoming the go-to option over hydraulic or pneumatic systems.

Why Electric Linear Actuators Are on the Rise

Electric actuators work by converting electrical energy into linear motion. That means you can move something in a straight line with a motor instead of using fluid power or air pressure. The benefits are easy to see:

- Precision: They allow accurate control over position, speed, and force.

- Low maintenance: No fluid leaks, air hoses, or constant monitoring.

Cleaner and quieter: Ideal for environments that require minimal noise and cleanliness.

- Energy-efficient: Use power only when moving, unlike hydraulic systems that need constant pressure.

These advantages are making electric actuators popular in both new designs and in retrofitting old machines with smarter, more efficient components.

Electric linear actuators are versatile. You can find them in a long list of applications, and each year, that list keeps growing. Below are four major industries where electric actuators are driving real change.

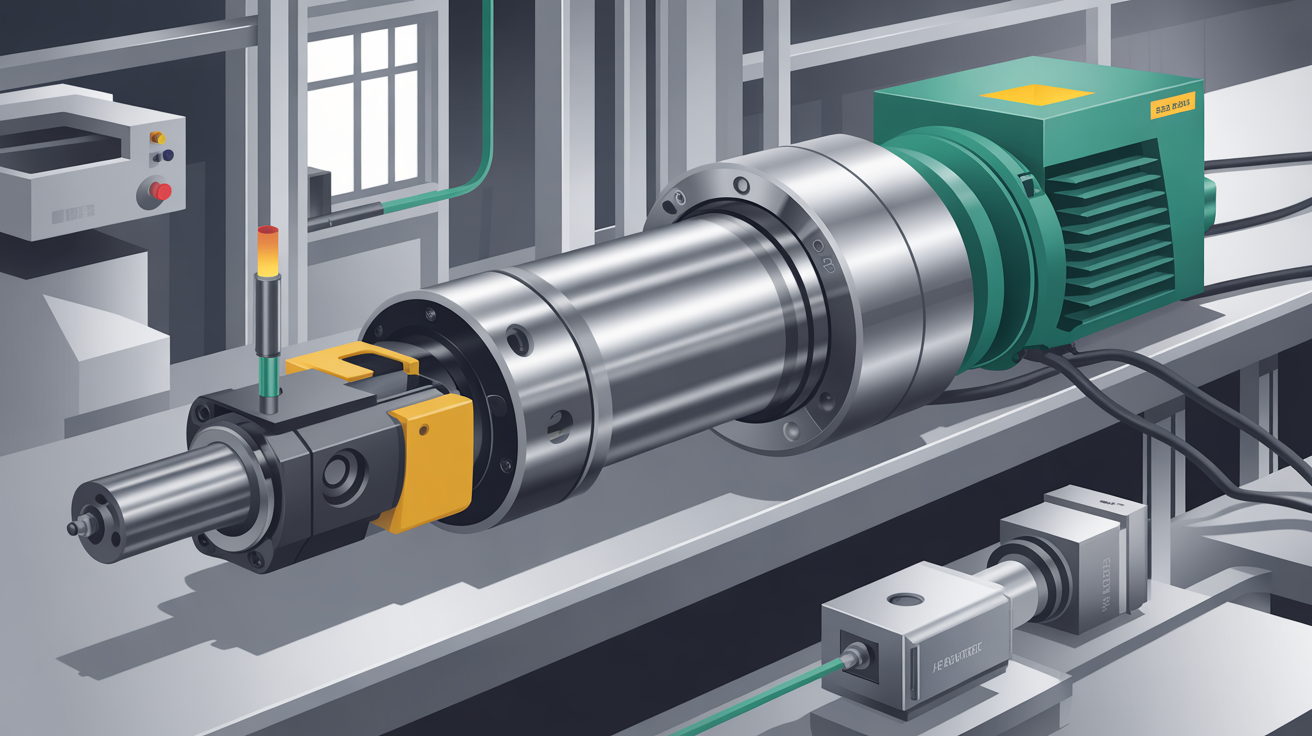

1. Machinery and Manufacturing

In the world of machines and production lines, precision and repeatability are non-negotiable. Actuators are responsible for tasks like adjusting conveyor belts, lifting parts for assembly, opening and closing valves, and managing cutting tools. Electric actuators do all of this with accurate motion control that can be easily integrated with programmable logic controllers (PLCs) and industrial robots.

Many factories are switching to electric systems because they’re easier to install, program, and scale. Actuators also improve safety — for example, by automating dangerous tasks that once required manual handling. As smart manufacturing continues to evolve, electric actuators will remain one of its key building blocks.

2. Agricultural Technology (Agrotech)

Farming isn’t what it used to be. Today’s agriculture involves automated tractors, greenhouse systems, smart irrigation, and livestock management, and actuators are part of all of it.

In greenhouses, electric actuators open and close windows or control the angle of solar panels depending on the weather. On farm equipment, they adjust seeding machines, sprayers, and cutting tools in real time, often based on sensor feedback. This automation helps farmers use resources more efficiently and boost yields without overworking the land.

Electric actuators also stand up to the tough conditions in agriculture. They handle dust, moisture, and outdoor use better than many alternatives. That’s why more agricultural machinery is now designed around electric motion systems from the start.

3. Medical Equipment and Healthcare

In the medical field, reliability and smooth motion are critical. You’ll find electric linear actuators in hospital beds, surgical chairs, imaging machines, and patient lifts. These devices need to be safe, quiet, and precise, and that’s what electric actuators deliver.

For patients, comfort matters. Actuators help beds recline, lifts move gently, and machines adjust without sudden jerks. For doctors and nurses, easy-to-control motion saves time and reduces effort during care or diagnosis.

Electric actuators are also ideal for mobility aids, such as motorized wheelchairs and adjustable home-care furniture. Their compact size and ability to sync with control systems make them perfect for the healthcare environment, where every movement must be controlled and consistent.

4. Construction and Heavy Equipment

In construction, strength and reliability are everything. Electric actuators are now used in building automation, heavy machinery, and adjustable equipment like work platforms, excavator attachments, and loaders.

They can lift heavy loads, adjust angles, or automate doors and hatches. And unlike hydraulic cylinders, electric actuators don’t need bulky hoses or fluid tanks, making them easier to maintain and safer to use.

Modern construction equipment also benefits from smart features. For example, actuators can be programmed to move only under certain conditions, preventing damage or misuse. In smart buildings, they’re used to adjust ventilation systems, louvers, skylights, and more.

The Future Is Automated

As more industries turn to automation, the demand for smart, efficient components is only going to grow. Electric actuators offer the performance and flexibility needed to support that growth from large-scale factories to remote farms and high-tech hospitals.

Companies are now designing entire systems around the capabilities of electric actuators. They’re easier to install, adapt well to automation software, and don’t require the same maintenance or safety checks as fluid-based systems. This leads to less downtime and better results across the board.

Electric actuators are also playing a role in the rise of Industry 4.0 — the movement toward interconnected, data-driven manufacturing. By integrating actuators with sensors and control software, operators can monitor performance, detect issues early, and optimize motion in real time. This is changing how people think about motion in industrial settings, not as something fixed and mechanical, but as something programmable, adaptive, and intelligent.

The growing role of electric linear actuators in modern industrial automation is no longer a trend, it’s a transformation. As industries look to reduce waste, improve safety, and increase precision, these compact devices are helping make it possible.

From agriculture to medicine, from factories to construction sites, electric actuators are quietly doing their job, moving things in the right direction. At Progressive Automations, we’ve been part of this journey, providing actuator solutions that power change in every corner of the automation world.

As more sectors adopt electric motion systems, the potential only expands. Faster machines. Smarter farms. Safer hospitals. Stronger buildings. With the right actuator, the possibilities are in motion.