Choosing between drywall and plaster impacts project timelines, budgets, and long-term building performance.

This guide helps homeowners, contractors, and renovators understand the main differences between these materials, examining installation methods, durability, and cost, so they can make informed decisions for 2026 building projects.

What Is the Difference Between Drywall and Plaster?

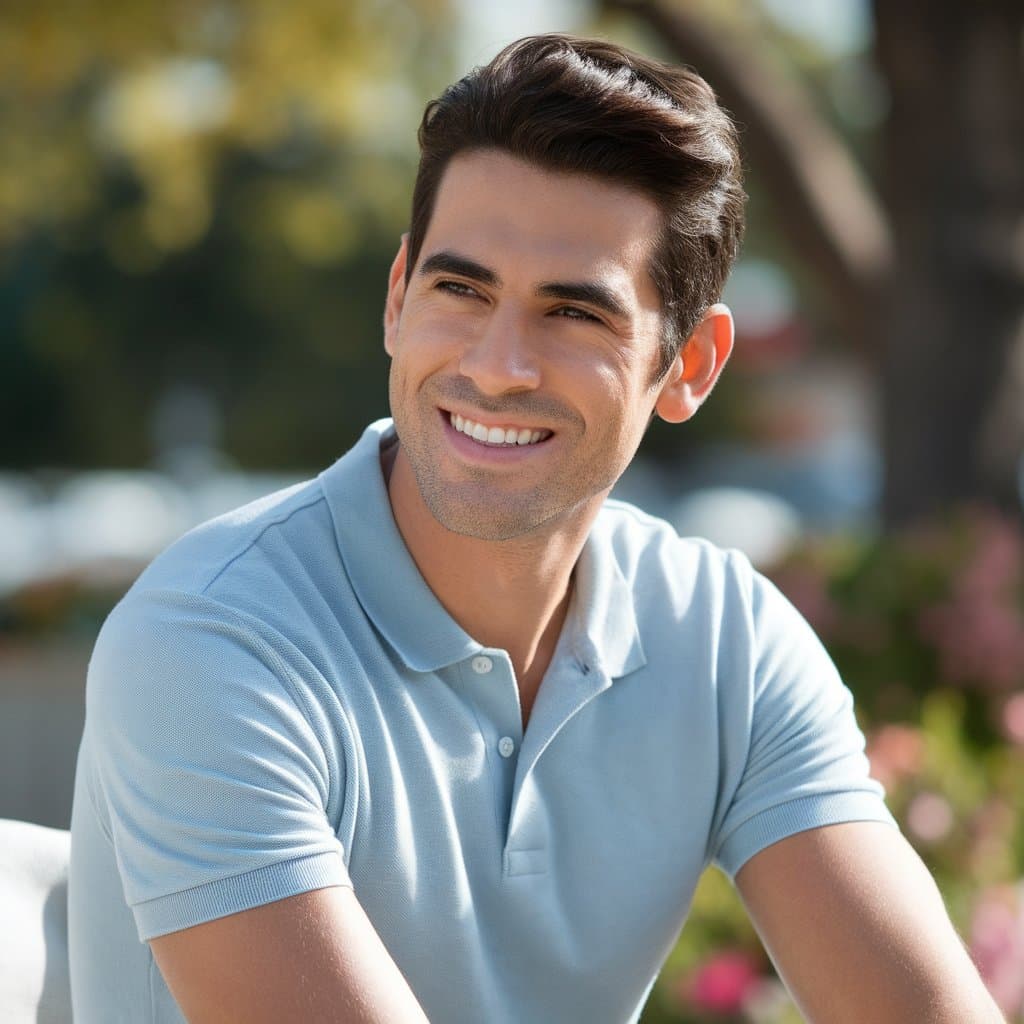

Drywall consists of gypsum panels, typically sold as pre-manufactured drywall boards measuring 4×8 feet or larger, fastened directly to wall studs with screws. Joints receive tape and compound for seamless finishing before painting.

Plaster, conversely, involves applying wet materials, traditionally lime, sand, and water, in multiple coats directly onto lath or masonry surfaces, creating hard, monolithic walls through labour-intensive troweling. According to Statista’s 2024 construction data, wallboard product sales in the United States show drywall’s dominant position in contemporary construction.

Today’s building landscape sees drywall accounting for most new residential and commercial interior wall installations, while plaster persists primarily in luxury renovations, historic restoration projects, and specialized applications where its unique properties justify higher costs.

Time, Skill, and Efficiency

Installation speed separates these materials. Competent crews hang and finish drywall rooms within days, with large panels covering extensive areas quickly, joints requiring only taping and mudding, and minimal specialized expertise sufficing for acceptable results.

Plaster demands weeks for completion, as each coat requires thorough drying before applying subsequent layers, with base coats, brown coats, and finish coats building thickness gradually.

Skilled plasterers ask for premium wages due to the technique required for achieving smooth, level surfaces through hand troweling, whereas drywall installation training takes considerably less time.

This efficiency gap explains why drywall dominates time-sensitive commercial projects and production housing, where labor costs and construction schedules directly impact profitability.

Durability, Performance, and Maintenance

Long-term performance characteristics favor different scenarios. Plaster’s dense, hard composition resists dents and impacts that readily damage drywall, while providing superior sound dampening and fire resistance due to thickness and mineral content.

However, plaster’s rigidity makes it prone to cracking as buildings settle or experience temperature fluctuations, with repairs requiring specialized skills. According to the AP, homeowner remodeling spending continues climbing, with much of this activity involving drywall repairs and improvements.

Drywall’s flexibility better accommodates minor structural movement, and damaged sections patch easily with readily available materials and basic DIY skills. Moisture-resistant and mold-resistant drywall formulations address traditional weaknesses, extending durability in bathrooms and basements.

Best Use Cases for Modern Construction

Material selection should align with project requirements and priorities. Drywall makes sense for most new residential construction, commercial tenant improvements, and energy-efficient building assemblies where insulation integration matters.

Its compatibility with modern building systems, like electrical, HVAC, and data cabling, streamlines installation compared to plaster’s solid mass. Plaster excels in high-end custom homes where distinctive hand-troweled textures justify costs, historic renovations requiring period-appropriate finishes, and sound-sensitive environments like recording studios or luxury condominiums.

Current building codes and sustainability considerations favor drywall’s recyclability and lower embodied energy compared to traditional plastering methods.

Smart material selection balances aesthetic goals, budget constraints, and performance requirements, making sure that interior finishes serve projects well throughout their intended lifespan.