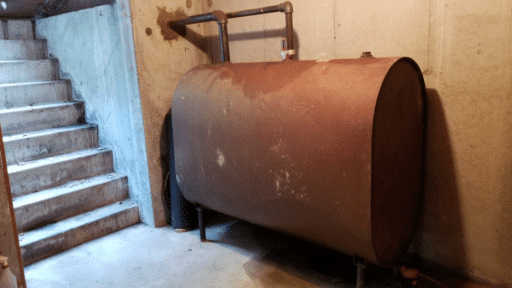

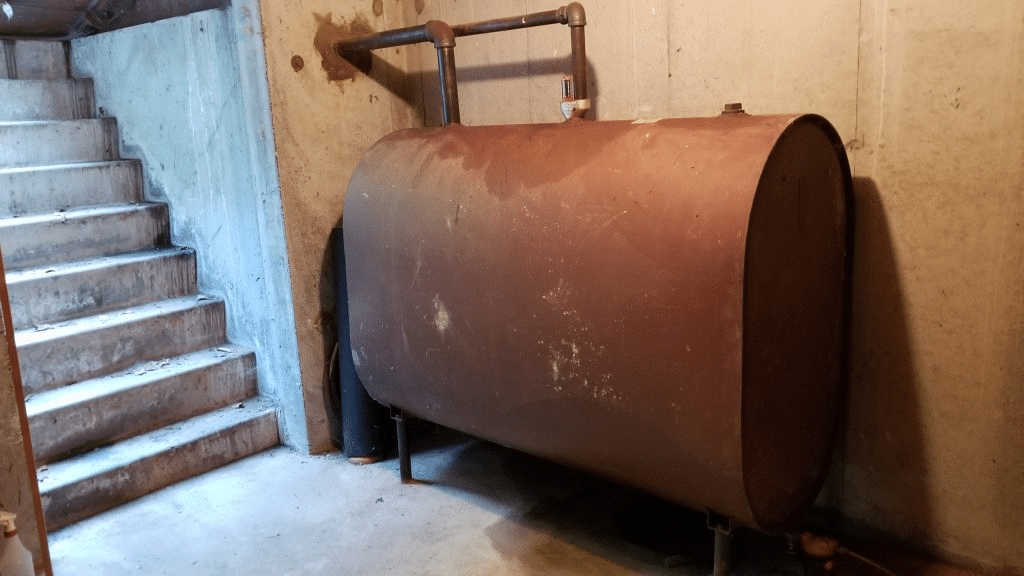

Heating oil tanks rarely draw attention. They sit quietly behind mechanical rooms or beneath paved surfaces, doing their job year after year. For many facilities, that reliability becomes an assumption—and assumptions can be risky.

As heating oil tanks age, they can introduce operational, environmental, and compliance challenges long before a visible failure occurs. For facilities managers, operations leaders, and environmental compliance professionals, recognizing early warning signs can make the difference between controlled planning and reactive decision-making.

This article outlines how heating oil tanks typically age, what signs may indicate declining condition, and when heating oil tank replacement planning becomes the practical path forward.

How Heating Oil Tanks Age in Real-World Facility Environments

Heating oil tanks do not fail suddenly. Most degrade gradually, shaped by environmental exposure, operating conditions, and maintenance history.

Age matters, but it rarely tells the full story.

- Internal corrosion may develop as condensation forms inside the tank and settles at low points.

- External corrosion can occur where tanks contact soil, concrete, or standing moisture.

- Mechanical stress from repeated fill cycles and temperature changes may affect seams and fittings over time.

- Legacy materials or coatings may no longer align with modern industry practices, even if the tank remains functional.

Practical example:

A municipal maintenance facility reviews its infrastructure during long-term capital planning. The heating oil tank still performs reliably, but inspection findings show early corrosion related to decades of seasonal moisture exposure. While no leak is present, the conditions suggest closer evaluation is warranted.

Warning Signs Your Heating Oil Tank May Be Reaching End of Life

Physical and Operational Red Flags

Some warning signs are visible. Others show up indirectly through equipment performance or maintenance patterns.

- Rust, pitting, or blistering paint, especially near seams or supports

- Fuel odors around the tank, piping, or fill area

- Staining or discoloration on concrete pads or nearby soil

- Recurring filter clogs or inconsistent burner operation

Individually, these issues may seem manageable. Together, they can point to declining tank integrity.

Practical example:

A healthcare facility experiences repeated fuel filter issues during winter months. What initially appears to be routine maintenance leads to an inspection that identifies internal corrosion contributing to fuel contamination.

Compliance and Documentation Gaps

Tank condition is only part of the risk picture. Documentation and compliance readiness matter just as much.

- Incomplete or outdated inspection records

- Equipment installed before current AST or UST guidance, without documented upgrades

- Missing secondary containment or monitoring systems

- Difficulty producing records during audits or third-party reviews

Documentation gaps can limit flexibility and increase pressure during regulatory interactions.

Practical example:

An environmental compliance officer preparing for a scheduled audit discovers that the most recent integrity testing predates current recordkeeping expectations. While the tank appears stable, the lack of documentation raises concerns.

Risks of Delaying Tank Replacement Planning

When a tank continues to operate, it is easy to postpone planning. Over time, that delay can shift risk from manageable to urgent.

- Unplanned outages may occur during peak heating demand

- Emergency response coordination can become rushed and disruptive

- Operational interruptions may affect tenants, patients, or critical services

- Regulatory scrutiny often increases after an incident rather than before one

Planning does not require immediate replacement. It provides visibility and options before time becomes a constraint.

Practical example:

An industrial facility defers tank upgrades due to competing priorities. A leak during a cold snap forces an emergency shutdown, diverting attention and resources from core operations.

When Replacement Becomes the More Practical Option

There comes a point when ongoing repairs and monitoring no longer provide meaningful risk reduction. Replacement planning often becomes more practical under certain conditions.

- Maintenance costs rise without extending service life

- Compatible parts or upgrades become difficult to source

- Modern monitoring systems cannot be effectively integrated

- Facility renovations or expansions are already planned

Replacement decisions are rarely about a single issue. They reflect cumulative risk and long-term facility strategy.

Practical example:

A university reviews several years of maintenance records and determines that phased replacement aligns better with its infrastructure roadmap than continued reactive repairs.

What a Planned Tank Replacement Process Typically Involves

A planned replacement approach emphasizes coordination, documentation, and continuity of operations.

- Condition assessments and record reviews to establish baseline risk

- Removal or decommissioning planning based on site constraints

- Installation of new tanks or systems aligned with current operational needs

- Integration of monitoring or leak detection systems, where appropriate

When scheduled proactively, replacement work can often be coordinated to reduce disruption.

Practical example:

A property manager schedules tank replacement during a low-demand period, coordinating removal and installation while maintaining normal building operations.

The Role of Full-Service Storage Tank Providers

Heating oil tanks require attention throughout their lifecycle. Many facilities benefit from working with providers that offer comprehensive storage tank services.

- Fuel tank inspection and maintenance to support day-to-day operations

- AST and UST services tailored to site-specific conditions

- Fuel tank installation and removal coordinated with compliance needs

- Environmental spill response services available during critical situations

A full-service approach can simplify communication and reduce handoffs when timing matters.

Practical example:

A hospital selects a provider capable of both routine inspections and emergency response, helping ensure continuity of care during infrastructure work.

Responsible Use and Compliance Considerations

Tank services are designed to support compliance efforts, not replace regulatory responsibility. Requirements vary by jurisdiction and facility type, and they change over time.

- Facility owners remain responsible for compliance decisions

- Service providers can assist with inspections, documentation, and best practices

- Proactive engagement may help reduce uncertainty during audits

- Clear records support informed, defensible decision-making

Practical example:

An EHS manager works with a tank services provider to organize inspection records ahead of a regulatory review, reducing last-minute pressure.

Conclusion: Plan Early to Maintain Control

Aging heating oil tanks rarely fail without warning. The signals are often subtle, and they are easy to overlook when operations run smoothly. Recognizing those signs early creates options.

Planned evaluation supports informed budgeting, thoughtful scheduling, and measured decision-making. In contrast, emergency response limits choices and increases disruption.

For many facilities, a professional tank assessment or compliance review is a reasonable next step. It does not commit anyone to immediate action. It simply provides clarity—and clarity is what allows facility leaders to stay in control.