Building a greenhouse often feels expensive, complicated, or out of reach for home gardeners.

Many assume it requires costly kits, professional tools, or advanced construction skills.

In reality, a functional greenhouse can be built affordably with simple materials and thoughtful planning.

This article shows how budget-friendly DIY greenhouse ideas can support plant growth without unnecessary spending.

It explains low-cost structures, materials that are easy to source, and step-by-step building methods that prioritize function over appearance.

From PVC hoop houses to recycled window builds, each option focuses on reducing costs while maintaining stability, light access, and airflow for reliable growing results.

6 DIY Greenhouse Ideas

Practical, low-cost greenhouse options that focus on simple construction, affordable materials, and efficient use of available space for home gardening.

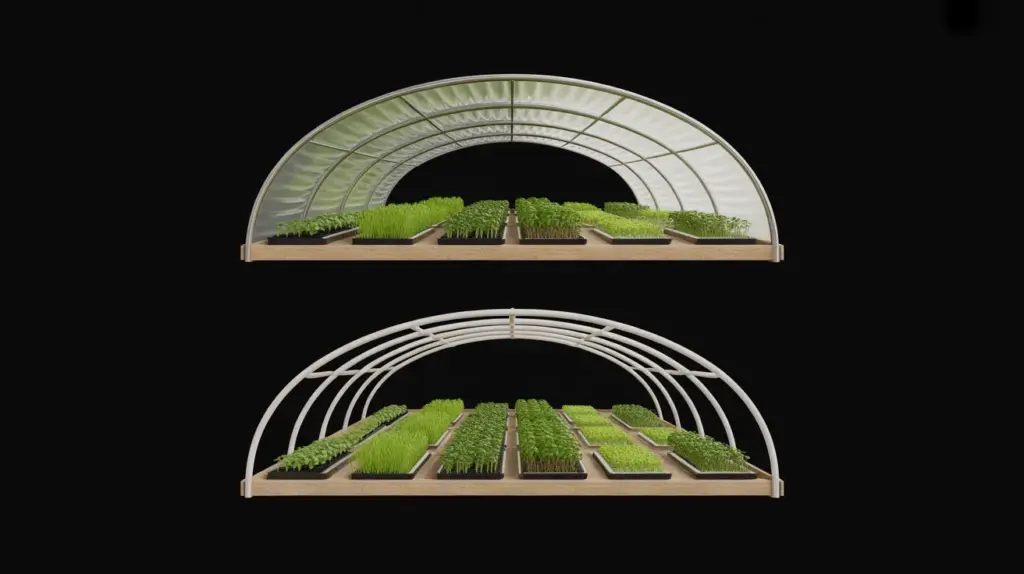

1. PVC Pipe Hoop Greenhouse

PVC pipe hoop greenhouses are among the most affordable options. Flexible PVC pipes form arches that are secured into the ground and covered with greenhouse plastic or clear sheets.

The structure is lightweight, easy to assemble, and suitable for seasonal growing.

Materials Needed

| Material | Suggested spec | Purpose |

|---|---|---|

| PVC pipe | 20–25 mm (3/4″–1″) | Hoop frame |

| Rebar stakes | 10–12 mm, ~45–60 cm | Anchors for PVC ends |

| Greenhouse plastic | 150–200 micron UV-stable | Main cover |

| Wiggle wire + channel OR battens | optional | Secure plastic long-term |

| Zip ties/rope | heavy-duty | Temporary fastening |

| Ground stakes | 6–10 pieces | Anchor plastic edges |

| Wooden base (optional) | simple rectangle | Adds stability |

How to make a PVC Pipe Hoop Greenhouse:

Select a sunny, open area where sunlight is available for most of the day, as this reduces the need for artificial heating.

Measure and mark the greenhouse footprint on the ground, keeping the size small to control material costs and make ventilation easier.

Drive rebar or wooden stakes firmly into the soil along both sides of the marked area to create strong anchor points for the frame.

Slide PVC pipes over the anchors and bend them into smooth arches, ensuring each hoop is evenly spaced for structural balance.

Secure a long PVC pipe along the top center of the hoops to prevent movement and sagging, especially during wind or rain.

Stretch a clear greenhouse plastic sheet over the frame on a calm day to avoid wrinkles and weak spots.

Fasten the plastic tightly using wooden battens, clamps, or zip ties, and secure the bottom edges by burying them in soil or weighing them down.

Create simple ventilation by adding a roll-up side or a basic door opening to prevent heat buildup during warmer days.

Cost control notes: PVC + plastic is cheaper than kits. UV-stable plastic lasts longer than thin tarps, saving replacement costs.

2. Cold Frame Greenhouse

Cold frames are small ground-level structures made from wood and a clear lid. They protect plants from frost and extend the growing season. It is best for seedlings.

Cold frames require minimal materials and are one of the cheapest greenhouse options.

Materials Needed

| Material | Suggested spec | Purpose |

|---|---|---|

| Wood boards | scrap wood works | Box |

| Clear lid | old window OR polycarbonate sheet | Light + insulation |

| Hinges | 2–3 | Lid opening |

| Screws | exterior-grade | Assembly |

| Weather stripping (optional) | basic foam strip | Reduce drafts |

How to DIY It

Choose a south-facing spot close to the house or garden beds where the structure will receive direct sunlight.

Build a low wooden box with the back side slightly higher than the front to allow the lid to slope toward the sun.

Secure the wooden boards with exterior screws to prevent gaps that let heat escape.

Attach a clear lid, such as an old window or plastic panel, using hinges so it can be opened and closed easily.

Seal gaps around the lid with simple weather stripping or overlapping wood to improve heat retention.

Vent the cold frame regularly by opening the lid slightly on warm days to avoid overheating young plants.

Cost control notes: Using an old window is usually the cheapest lid option.

3. Lean-To Greenhouse

Lean-to greenhouses are built against an existing wall, such as a house, shed, or garage.

The supporting wall reduces material needs and provides additional warmth. This design is cost-effective and works well in limited spaces.

Materials Needed

| Material | Suggested spec | Purpose |

|---|---|---|

| Timber for the frame | basic 2×2 or 2×3 | Structure |

| Covering | greenhouse plastic OR old windows | Walls/roof |

| Screws + brackets | exterior-grade | Strength |

| Sealant | silicone/caulk | Seal edges |

| Door hardware | hinges + latch | Access |

| Vent option | flap window or roof vent | Airflow |

How to DIY It

Select an existing wall that receives good sunlight and remains dry, as this wall will act as insulation and structural support.

Construct a narrow wooden base frame against the wall to reduce material use and improve heat efficiency.

Build a simple front frame using vertical wooden posts, keeping the height lower at the front to create a sloped roof.

Attach clear plastic sheets or recycled windows to the frame, ensuring all joints are tightly sealed.

Angle the roof toward the sun to improve light exposure and allow rainwater to drain naturally.

Install at least one opening panel or vent near the top to allow warm air to escape when temperatures rise.

Cost control notes: One wall is “free,” so material cost drops compared to free-standing builds.

4. Recycled Window Greenhouse

Old windows or glass doors can be reused to form greenhouse walls. A simple wooden frame holds the windows in place, providing better insulation than plastic alone.

Salvaged materials from renovation projects help reduce overall costs.

Materials Needed

| Material | Suggested spec | Purpose |

|---|---|---|

| Old windows/doors | similar sizes help | Panels |

| Timber frame | sturdy wood | Support structure |

| Screws | exterior-grade | Fixing windows |

| L-brackets | optional | Strength at corners |

| Sealant + weather strip | recommended | Draft control |

| Roof cover | polycarbonate/plastic | The roof is often the easiest non-glass |

How to DIY It

Collect recycled windows of similar size to simplify framing and reduce wasted materials.

Lay out the windows on the ground to decide the greenhouse shape before cutting any wood.

Build a strong wooden base and wall frame that supports the weight of the glass without shifting.

Fix the windows securely to the frame using screws, taking care not to overtighten and crack the glass.

Use plastic or polycarbonate sheets for the roof to reduce weight and construction difficulty.

Seal all edges and joints with weatherproof sealant to reduce heat loss and drafts.

Add opening windows or roof vents to maintain airflow and temperature balance.

Cost control notes: Salvage yards and renovation sites can provide low-cost windows. This build lasts longer than thin-plastic options.

5. Pallet Wood + Plastic Greenhouse

Pallet wood greenhouses use reclaimed pallets for framing. Disassembled pallets provide free or low-cost lumber.

When paired with plastic sheeting, this structure offers a sturdy and affordable growing space.

Materials Needed

| Material | Suggested spec | Purpose |

|---|---|---|

| Pallets | heat-treated if possible | Lumber source |

| Screws | exterior-grade | Assembly |

| Plastic sheeting | UV-stable recommended | Cover |

| Battens (thin wood strips) | yes | Trap plastic |

| Door frame wood | simple | Access |

| Staples (optional) | only with battens | Temporary hold |

How to DIY It

Disassemble pallets carefully and select straight boards to build a stable base and frame.

Assemble a rectangular base and anchor it securely to prevent movement during wind.

Fix vertical supports at corners and midpoints, adding diagonal braces for strength.

Create a sloped roof to prevent water accumulation on the plastic covering.

Stretch greenhouse plastic tightly over the structure and secure it using wooden battens rather than staples alone.

Leave planned openings for doors or vents to control airflow and humidity inside the greenhouse.

Cost control notes: Free pallets keep costs low, but do not use chemically treated wood for food-growing spaces.

6. Plastic Bottle Greenhouse

Plastic bottle greenhouses use discarded bottles as wall panels.

Bottles are cleaned, stacked, and attached to a basic wooden or bamboo frame.

This method reduces waste and eliminates the need for glass or plastic sheets. It works best for small gardens and mild climates.

Materials Needed

| Material | Suggested spec | Purpose |

|---|---|---|

| Clear plastic bottles | same size = easier | “Panels” |

| Bamboo/wood poles | light but strong | Frame |

| Wire/screws | sturdy | Fixing columns |

| Cutting tool | required | Bottle prep |

| Plastic sheet (roof) | recommended | Roof sealing |

How to DIY It

Collect clear plastic bottles of the same size to reduce gaps and improve heat retention.

Remove labels, wash the bottles, and cut off the bottoms so they can slide into one another.

Assemble long vertical bottle columns and prepare enough to cover all wall sections.

Build a lightweight wooden or bamboo frame with evenly spaced vertical supports.

Attach the bottle columns tightly to the frame to limit air gaps.

Cover the roof with a plastic sheet rather than bottles to ensure proper drainage and sealing.

Add a small opening or flap to prevent excessive heat buildup on sunny days.

Cost control notes: Material cost is low, labor time is high.

What are Common Greenhouse Mistakes?

Wrong plastic choice: Thin plastic tears fast; UV-stable greenhouse film lasts longer and is cheaper over time.

No vent plan: Heat buildup can ruin plants even in cool weather. A vent/roll-up side is not optional.

Poor anchoring: Wind damage is one of the biggest budget killers. Edges must be buried, weighted, or battened down.

Bad location: Too much shade reduces performance and pushes unnecessary spending on heating.

Oversized first build: A larger area increases cost, ventilation complexity, and repairs.

The Bottom Line

Building a greenhouse on a budget is achievable with careful planning, simple designs, and the right material choices.

Cost-effective DIY greenhouse ideas rely on sunlight placement, compact sizing, and materials that are easy to source or reuse.

Starting with a small structure helps control expenses and makes temperature management easier.

Frames made from PVC, pallets, or recycled windows offer stability without high costs, while proper sealing and ventilation prevent common issues that lead to repairs or plant loss.

A low-cost greenhouse does not need to look complex to work well.

Practical construction choices support consistent growth while keeping long-term maintenance and replacement costs manageable.

Frequently Asked Questions

Do Greenhouses Stay Warm in Winter?

They hold heat better than open air, but warmth depends on sun exposure, sealing, and insulation. In colder areas, extra protection like double-layer plastic or thermal mass (water containers) helps.

Is It Cheaper to Buy or Build a Greenhouse?

Building is usually cheaper when recycled materials or PVC-and-plastic designs are used, especially for small to medium sizes.